Page 2 - Parker - Fulflo Abso-Mate Cartridges

P. 2

Fulfl o Abso-Mate Cartridges

™

®

Specifi cations

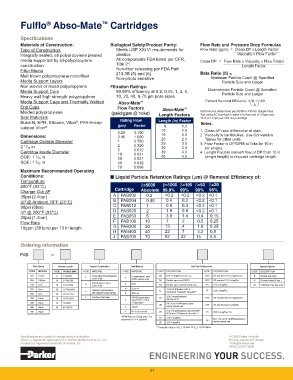

Materials of Construction: Biological Safety/Product Purity: Flow Rate and Pressure Drop Formulas

Type of Construction Meets USP XXi VI requirements for Flow Rate (gpm) = Clean DP x Length Factor

Integrally sealed, all-polypropylene pleated plastics Viscosity x Flow Factor

media supported by all-polypropylene All components FDA listed per CFR, Clean DP = Flow Rate x Viscosity x Flow Factor

construction Title 21 Length Factor

Filter Media Non-fi ber releasing per FDA Part

Melt blown polypropylene microfi ber 210.3B (5) and (6) Beta Ratio (ß) =

Non-photo sensitive

Upstream Particle Count @ Specifi ed

Media Support Layers Particle Size and Larger

Non-woven or mesh polypropylene Filtration Ratings:

Media Support Core 99.98% effi ciency at 0.2, 0.45, 1, 2, 5, Downstream Particle Count @ Specifi ed

Particle Size and Larger

Heavy wall high strength polypropylene 10, 20, 40, & 70 μm pore sizes

Media Support Cage and Thermally Welded Abso-Mate Percent Removal Effi ciency = ß-1 100

™

End Caps Flow Factors Abso-Mate ß

™

Molded polypropylene (psid/gpm @ 1cks) Length Factors Performance determined per ASTM F-795-88. Single-Pass

Test using AC test dust in water at a fl ow rate of 3.5gpm per

Seal Materials 10 in (13.2 lpm per 254 mm) cartridge.

Buna-N, EPR, Silicone, Viton , PFA Encap- Rating Flow Length (in) Factor Notes:

®

sulated Viton ® (μm) Factor 9 1.0

0.20 3.100 10 1.0 1. Clean P ispsi differential at start.

Dimensions: 0.45 1.000 19 2.0 2. Viscosity is centistokes. Use Conversion

Tables for other units.

Cartridge Outside Diameter 1 0.750 20 2.0 3. Flow Factor is DP/GPM at 1cks for 10 in

29

3.0

2 ⁄ 16 in 2 0.300 30 3.0 (or single).

11

Cartridge Inside Diameter 5 0.072 39 4.0 4. Length Factors convert fl ow or DP from 10 in

0.031

10

DOE: 1 ⁄ 16 in 20 0.021 40 4.0 (single length) to required cartridge length.

1

SOE: 1 ⁄ 32 in 40 0.012

5

70 0.008

Maximum Recommended Operating

Conditions: n Liquid Particle Retention Ratings (m) @ Removal Effi ciency of:

Temperature

200°F (93°C) =5000 =1000 =100 =50 =20

Change Out ∆P Cartridge Absolute 99.9% 99% 98% 95%

35psi (2.4bar) A PAB002 0.2 <0.2 <0.2 <0.2 <0.1

∆P @ Ambient 70°F (21°C) B PAB004 0.45 0.4 0.2 <0.2 <0.1

90psi (6bar) C PAB010 1 0.8 0.4 <0.2 <0.1

∆P @ 200°F (93°C) D PAB020 2 1.9 0.8 <0.2 <0.1

20psi (1.4bar) E PAB050 5 3.8 1.4 0.4 0.15

Flow Rate F PAB100 10 7 2 0.5 0.25

10gpm (38 lpm) per 10 in length G PAB200 20 13 4 1.8 0.35

H PAB400 40 22 7 3.2 0.8

J PAB700 70 52 22 15 5.5

Ordering Information

PAB —

Filter Rating Nominal Length Support Construction Seal Material End Cap Confi guration Special Options

CODE MICRON CODE INCHES (MM) CODE MATERIAL CODE MATERIAL CODE DESCRIPTION CODE DESCRIPTION CODE DESCRIPTION

002 0.2μm 9 9 ⁄ 8 (244) F Glass-fi lled Polypropylene P Polyethylene Foam AR 020 O-ring/Recessed cap SSC SS inserted 226 O-ring/Closed B Bubble-point test

5

004 0.45μm 10 9 13 ⁄16 (249) (core only) (DOE gasket only) DO Double open end (DOE) SSF SS inserted 226 O-ring/Fin R DI water rinse (5 min.)

304 Stainless Steel

010 1μm 19 19 5 ⁄ 8 (498) G (core only) E EPR DX Double open end/extended core TC 222 O-ring/Flat Z6 Individual Poly bag only

020 2μm 20 19 15 ⁄16 (506) Natural Polypropylene N Buna-N LL 120/120 (Filterlite LMO & TF 222 O-ring/Fin

A Nuclepore Polymeric Vessels)**

050 5μm 29 29 ¼ (743) (All support components) S Silicone

100 10μm 30 30 1 ⁄16 (764) X Coreless Cartridge PFA-Encapsulated LR 120 O-ring/Recessed STC SS inserted 222 O-ring/Closed

(Nuclepore)**

T Viton ® (222, 226 &

200 20μm 39 39 (991) O-ring only)* Std. open end/Polypropylene

OB STF SS inserted 222 O-ring/Fin

400 40μm 40 40 (1016) V Viton ® spring closed end

700 70μm X No seal material PR 213 O-ring/Recessed cap (Ametek ® TX 222 O-ring/Flex Fin

& Parker LT Polymeric Vessels) **

*PFA/Viton is O-ring only, T is SC 226 O-ring/Flat

expanded PTFE gaskets XB Ext. core open end/Polypropylene

SF 226 O-ring/Fin spring closed end

**Available only in 9 5 ⁄ 8 ˝ (-9) and 19 5 ⁄ 8 ˝ (-10) lengths

Specifi cations are subject to change without notifi cation. © 2009 Parker Hannifi n

Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc. Process Advanced Filtration

Ametek is a registered trademark of Ametek, Inc. All Rights Reserved

SPEC-C2047 08/09

21