Page 1 - Colder Products Company - DrumQuik Pro Dispensing Systems for Professional Chemical Management

P. 1

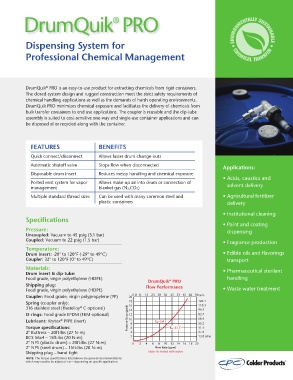

DrumQuik PRO

®

Dispensing System for

Professional Chemical Management

DrumQuik PRO is an easy-to-use product for extracting chemicals from rigid containers.

®

The closed-system design and rugged construction meet the strict safety requirements of

chemical handling applications as well as the demands of harsh operating environments.

DrumQuik PRO minimizes chemical exposure and facilitates the delivery of chemicals from

bulk transfer containers to end use applications. The coupler is reusable and the dip-tube

assembly is suited to cost-sensitive one-way and single-use container applications and can

be disposed of or recycled along with the container.

FEaTUrES BENEFiTS

Quick connect/disconnect Allows faster drum change-outs

Automatic shutoff valve Stops flow when disconnected

applications:

Disposable drum insert Reduces messy handling and chemical exposure

• Acids, caustics and

Ported vent system for vapor Allows make-up air into drum or connection of

management blanket gas (N2,CO2) solvent delivery

Multiple standard thread sizes Can be used with many common steel and • Agricultural fertilizer

plastic containers delivery

• Institutional cleaning

Specifications

• Paint and coating

Pressure: dispensing

Uncoupled: Vacuum to 45 psig (3.1 bar)

Coupled: Vacuum to 22 psig (1.5 bar)

• Fragrance production

Temperature:

Drum insert: -20° to 120°F (-29° to 49°C) • Edible oils and flavorings

Coupler: 32° to 120°F (0° to 49°C) transport

Materials: • Pharmaceutical sterilant

Drum insert & dip-tube:

Food grade, virgin polyethylene (HDPE) DrumQuik PrO handling

®

Shipping plug: Flow Performance

Food grade, virgin polyethylene (HDPE) • Waste water treatment

Coupler: Food grade, virgin polypropylene (PP) 20 0.0 8 15 23 30 38 45 53 61 68 76 (lpm)

Spring (coupler only): 18 124.1

110.3

®

316 stainless steel (Hastelloy C optional) 16 96.5

14

O-rings: Food grade EPDM (FKM optional) 12 82.7

Lubricant: Krytox PFPE (inert) Pressure Drop (psid) 10 8 C v ~3.6 68.9

®

55.2

Torque specifications: 6 K v ~51.7 41.4

2" Buttress – 20ft-lbs (27 N-m) 4 27.6

BCS 56x4 – 15ft-lbs (20 N-m) 2 13.8 (kPa)

2" NPS (plastic drum) – 20ft-lbs (27 N-m) 0 2 4 6 8 10 12 14 16 18 20

2" NPS (steel drum) – 15ft-lbs (20 N-m) Flow Rate (gpm)

Shipping plug – hand tight Note: As tested with water.

NOTE: The torque specifications listed above are general recommendations

which may need to be adjusted + or – depending on specific application.