Page 2 - Parker - Flo-Pac + Filter Cartridges

P. 2

®

Flo-Pac + Filter Cartridges

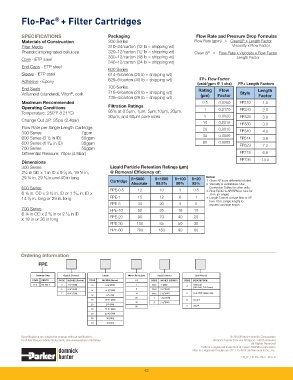

SPECIFICATIONS Packaging Flow Rate and Pressure Drop Formulas

Materials of Construction 300 Series Flow Rate (gpm) = CleanΔP x Length Factor

Filter Media 310–24/carton (12 lb ≈ shipping wt) Viscosity x Flow Factor

Phenolic impregnated cellulose 320–12/carton (12 lb ≈ shipping wt) Clean ΔP = Flow Rate x Viscosity x Flow Factor

330–12/carton (18 lb ≈ shipping wt) Length Factor

Core - ETP steel

340–12/carton (24 lb ≈ shipping wt)

End Caps - ETP steel

600 Series

Sleeve - ETP steel 614–6/carton (20 lb ≈ shipping wt)

Adhesive - Epoxy 629–6/carton (40 lb ≈ shipping wt) FP+ Flow Factor

(psid/gpm @ 1 cks) FP+ Length Factors

700 Series

End Seals Rating Flow Length

Vellumoid (standard), Viton , cork 718–6/carton (20 lb ≈ shipping wt) (μm) Factor Style Factor

®

736–4/carton (26 lb ≈ shipping wt)

Maximum Recommended 0.5 0.0260 FP310 1.0

Operating Conditions Filtration Ratings 1 0.0170 FP320 2.0

Temperature: 250°F (121°C) 95% at 0.5μm, 1μm, 5μm,10μm, 20μm,

30μm, and 60μm pore sizes 5 0.0020 FP329 3.0

Change Out ΔP: 35psi (2.4bar)

10 0.0018 FP330 3.0

Flow Rate per Single Length Cartridge: 20 0.0010

300 Series 7gpm FP340 4.0

600 Series (3 ½ in ID) 50gpm 30 0.0009 FP614 3.6

600 Series (1 ⁄ 16 in ID) 35gpm 60 0.0005

9

FP629 7.2

700 Series 50gpm

Differential Pressure: 70psi (4.8bar) FP718 6.5

FP736 13.0

Dimensions

300 Series Liquid Particle Retention Ratings (μm)

2½ in OD x 1 in ID x 9 ⁄ 8 in, 19 ¾ in, @ Removal Effi ciency of:

5

5

29 ¼ in, 29 ⁄ 8 in and 40 in long ß=5000 ß=1000 ß=100 ß=20 Notes:

Cartridge 1. Clean ΔP is psi differential at start.

Absolute 99.9% 99% 95% 2. Viscosity is centistokes. Use

600 Series FPE-0.5 12 10 3 0.5 Conversion Tables for other units.

6 ¼ in. OD x 3 ½ in. ID or 1 ⁄ 16 in. ID x 3. Flow Factor is ΔP/GPM at 1cks for

9

10 in. (or single).

3

14 ⁄ 8 in. long or 29 in. long FPE-1 15 12 6 1 4. Length Factors convert fl ow or ΔP

from 10 in. (single length) to

FPE-5 30 20 9 5 required cartridge length.

700 Series FPE-10 50 35 18 10

1

5

6 ¼ in OD x 2 ⁄ 8 in or 2 ⁄ 8 in ID

x 18 in or 36 in long FPE-20 90 70 40 20

FPE-30 100 85 50 30

FPE-60 200 150 90 60

Ordering Information

FPE

Cartridge Code Outside Diameter Length Micron Rating (μm) Inside Diameter Seal Material

CODE DESCR. CODE INCHES (Series) CODE INCHES (Series) 0.5 CODE INCHES (SERIES) CODE DESCRIPTION

FPE Flo-Pac + 3 2 ½" (300) 10 9 5 ⁄ 8 " (300) 1 None 1" (300) Vellumoid

A

(300, 600, 700 Series)

6 6 ¼" (600) 5 None 3 ½" (600)

14 14 3 ⁄ 8 " (600)

7 6 ¼" (700) 10 None 2 5 ⁄ 8 " (700) C Cork (700 Series Only)

18 18" (700)

9

20 1 1 ⁄ 16 " (600)

20 19 ¾" (300) N Buna-N

30 8 2 1 ⁄ 8 " (700)

29 29" (600)

60 V Viton ®

29 29 ¼" (300)

30 29 5 ⁄ 8 " (300)

36 36 (700)

40 40 (300)

Specifi cations are subject to change without notifi cation. © 2010 Parker-Hannifi n Corporation

For User Responsibility Statement, see www.parker.com/safety domnick hunter Process Filtration - North America

All Rights Reserved

Fulfl o is a registered trademark of Parker-Hannifi n Corporation

Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc.

DS_IP_Flo-Pac Plus Rev. A

43