Page 4 - Parker - Fulflo Honeycomb Filter Cartridges

P. 4

™

®

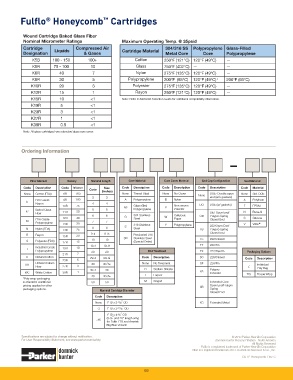

Fulfl o Honeycomb Cartridges

Wound Cartridge Baked Glass Fiber

Nominal Micrometer Ratings Maximum Operating Temp. @ 35psid

Cartridge Compressed Air 304/316 SS Polypropylene Glass-Filled

Liquids Cartridge Material

Designation & Gases Metal Core Core Polypropylene

K5B 100 - 150 100+ Cotton 250°F (121°C) 120°F (49°C) —

K5R 75 - 100 10 Glass 750°F (402°C) — —

K6R 40 7 Nylon 275°F (135°C) 120°F (49°C) —

K8R 30 5 Polypropylene 200°F (93°C) 120°F (49°C) † 200°F (93°C)

K10R 20 3 Polyester 275°F (135°C) 120°F (49°C) —

K12R 15 1 Rayon 250°F (121°C) 120°F (49°C) —

K15R 10 <1 Note: Refer to Materials Selection Guide for additional compatibility information.

K19R 5 <1

K23R 3 <1

K27R 1 <1

K39R 0.5 <1

Note: All glass cartridges have standard glass core cover.

Ordering Information

–

Filter Medium Density Nominal Length Core Material Core Cover Material End Cap Confi guration Seal Material

Code Description Code Micron Size Code Description Code Description Code Description Code Material

Code

(Inches)

None Cotton (FDA) 6R 150 None Tinned Steel None No Cover None DOE- Double open None Std. DOE

3 3 end (w/o gaskets)

FDA Grade 8R 100 A Polypropylene B Nylon A Polyfoam

E

Rayon 4 4 DO DOE (w/ gaskets)

10R 75 Glass-fi lled Non-woven E EPDM

A3 V

Baked Glass 5 5 Polypropylene Polester

K* 11R 50 N Buna-N

Fiber Std. Open End/

6 6 304 Stainless Cellulosic OB Polypro Spring

12R 40 G Steel W Paper S Silicone

FDA Grade Closed End

M 7 7

Polypropylene

13R 30 316 Stainless Y Polypropylene 222/Open End/ V Viton ®

8 8 S Steel

N Nylon (FDA) 25 TB Polypro Spring

14R

R Rayon 15R 20 9-4 9- 7 ⁄8 Passivated 316 Closed End

SR Stainless Steel TC 222/Closed

S Polyester (FDA) 10 10 (Special Order)

17R 15

19-4 19-½ TF 222/Fin

Industrial Grade 10

T 19R

Polypropylene 20 20 End Treatment TX 222/Flex fi n Packaging Options

21R 7

U Natural Cotton 29-4 29-¼ Code Description SC 226/Closed Code Description

23R 5

Unbaked Glass None No Treatment SF 226/Fin

UK 30 30- 3 ⁄16 Individual

Fiber 27R 3 Z Poly Bag

39-4 39 D Sodium Silicate XA Polypro

WC White Cotton 39R 1 Extender TIS Tissue Wrap

40 40- 3 ⁄16 L Laquer

*Poly wrap packaging

is standard. Additional 50 50 M Singed Extended Core

pricing applies for other XB Open End/Polypro

packaging options. Spring

Nominal Cartridge Diameter

Closed End

Code Description

None 1" ID x 2- 7 ⁄16 " OD XC Extended Metal

-2 1" ID x 2- 11 ⁄16 " OD

1" ID x 4-½ " OD

(9- 7 ⁄8 " and 20" length only)

-45

for Fulfl o LTG and Ametek

Big Blue Vessels

Specifi cations are subject to change without notifi cation. © 2010 Parker-Hannifi n Corporation

For User Responsibility Statement, see www.parker.com/safety domnick hunter Process Filtration - North America

All Rights Reserved

Fulfl o is a registered trademark of Parker-Hannifi n Corporation

Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc.

DS_IP_Honeycomb Rev. C

69