Page 2 - Parker - Power Generation Markets

P. 2

The Parker Solution

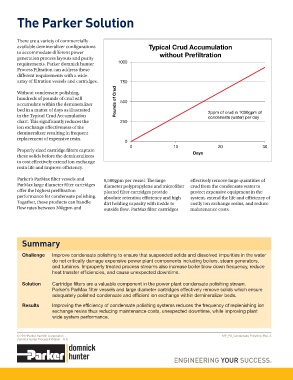

Th ere are a variety of commercially

available demineralizer confi gurations Typical Crud Accumulation

to accommodate diff erent power without Prefiltration

generation process layouts and purity

requirements. Parker domnick hunter 1000

Process Filtration can address these

diff erent requirements with a wide

array of fi ltration vessels and cartridges. 750

Without condensate polishing,

hundreds of pounds of crud will

accumulate within the demineralizer Pounds of Crud 500

bed in a matter of days as illustrated 2ppm of crud in 1000gpm of

in the Typical Crud Accumulation condensate (water) per day

chart. Th is signifi cantly reduces the 250

ion exchange eff ectiveness of the

demineralizer resulting in frequent

replacement of expensive resin.

0

0 10 20 30

Properly sized cartridge fi lters capture

Days

these solids before the demineralizers

to cost eff ectively extend ion exchange

resin life and improve effi ciency.

Parker’s ParMax fi lter vessels and 9,500gpm per vessel. Th e large eff ectively remove large quantities of

ParMax large diameter fi lter cartridges diameter polypropylene and microfi ber crud from the condensate water to

off er the highest prefi ltration pleated fi lter cartridges provide protect expensive equipment in the

performance for condensate polishing. absolute retention effi ciency and high system, extend the life and effi ciency of

Together, these products can handle dirt holding capacity with inside to costly ion exchange resins, and reduce

fl ow rates between 300gpm and outside fl ow. ParMax fi lter cartridges maintenance costs.

Summary

Challenge Improve condensate polishing to ensure that suspended solids and dissolved impurities in the water

do not critically damage expensive power plant components including boilers, steam generators,

and turbines. Improperly treated process streams also increase boiler blow down frequency, reduce

heat transfer effi ciencies, and cause unexpected downtime.

Solution Cartridge fi lters are a valuable component in the power plant condensate polishing stream.

Parker’s ParMax fi lter vessels and large diameter cartridges effectively remove solids which ensure

adequately polished condensate and effi cient ion exchange within demineralizer beds.

Results Improving the effi ciency of condensate polishing systems reduces the frequency of replenishing ion

exchange resins thus reducing maintenance costs, unexpected downtime, while improving plant

wide system performance.

© 2012 Parker-Hannifi n Corporation MP_PG_Condensate Polishing Rev. A

domnick hunter Process Filtration - N.A.