Page 255 - Wago_PCB_TerminalBlocksConnectors_Volume2_2015_US

P. 255

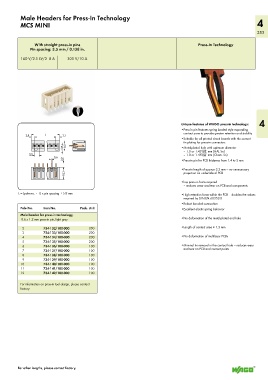

Male Headers for Press-In Technology

MCS MINI 4

253

With straight press-in pins Press-In Technology

Pin spacing: 3.5 mm / 0.138 in.

160 V/2.5 kV/2 8 A 300 V/10 A

4

Unique features of WAGO press-in technology:

• Press-in pin features spring-loaded style expanding

contact zone to provide greater retention and stability

2,8 <________L ________> 3,1

__> > > __> • Suitable for all printed circuit boards with the correct

tin plating for press-in connectors

> 4,35 (_ 8,5_) __ > _ _ • Metal-plated hole with optimum diameter

– 1.0 or 1.45

mm (HAL Sn)

3,5 – 1.0 or 1.45 –0.00 mm (Chem. Sn)

__> > 0,6

> __> 2,9 __> • Press-in pin for PCB thickness from 1.4 to 3 mm

<_10,3_> • Press-in length of approx 3.2 mm — no unnecessary

projection on underside of PCB

• low press-in force required

– reduces wear and tear on PCB and components

L = (pole no. – 1) x pin spacing + 5.9 mm • High retention force within the PCB — doubles the values

required by DIN EN 60352-5

• Robust bonded connection

Pole No. Item No. Pack. Unit • Excellent elastic spring behavior

Male header for press-in technology,

0.6 x 1.2 mm press-in pin, light gray • No deformation of the metal-plated end hole

2 734-132/100-000 200 • Length of contact area ≥ 1.3 mm

3 734-133/100-000 200

4 734-134/100-000 200 • No deformation of multilayer PCBs

5 734-135/100-000 200

6 734-136/100-000 100 • Minimal tin removal in the contact hole — reduces wear

7 734-137/100-000 100 and tear on PCB and contact points

8 734-138/100-000 100

9 734-139/100-000 100

10 734-140/100-000 100

11 734-141/100-000 100

12 734-142/100-000 100

For information on press-in tool design, please contact

factory.

For other lengths, please contact factory.