Page 2 - Parker - Metalworking

P. 2

The Parker Solution

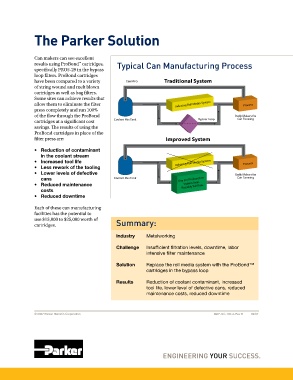

Can makers can see excellent

results using ProBond™ cartridges, Typical Can Manufacturing Process

specifically PRO5-29 in the bypass

loop filters. ProBond cartridges

have been compared to a variety

of string wound and melt blown

cartridges as well as bag filters.

Some sites can achieve results that

allow them to eliminate the filter

press completely and run 100%

of the flow through the ProBond

cartridges at a significant cost

savings. The results of using the

ProBond cartridges in place of the

filter press are:

• Reduction of contaminant

in the coolant stream

• Increased tool life

• Less rework of the tooling

• Lower levels of defective

cans

• Reduced maintenance

costs

• Reduced downtime

Each of these can manufacturing

facilities has the potential to

use $15,000 to $25,000 worth of Summary:

cartridges.

Industry Metalworking

Challenge Insufficient filtration levels, downtime, labor

intensive filter maintenance

Solution Replace the roll media system with the ProBond™

cartridges in the bypass loop

Results Reduction of coolant contaminant, increased

tool life, lower level of defective cans, reduced

maintenance costs, reduced downtime

© 2007 Parker Hannifin Corporation MAP-NC-100-A-Rev B 09/07