Page 51 - Parker - Pressure Control Valves

P. 51

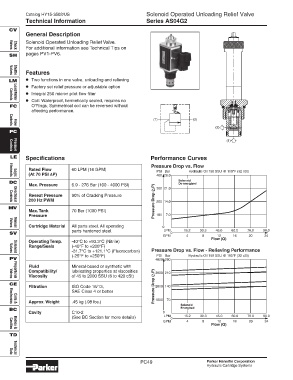

Catalog HY15-3502/US Solenoid Operated Unloading Relief Valve

Technical Information Series AS04G2

CV

General Description

Solenoid Operated Unloading Relief Valve.

For additional information see Technical Tips on

Check

Valves

SH pages PV1-PV6.

Features

Valves

Shuttle

LM • Two functions in one valve, unloading and relieving

• Factory set relief pressure or adjustable option

• Integral 250 micron pilot flow filter

• Coil: Waterproof, hermetically sealed, requires no

Controls

Load/Motor

FC O’Rings; Symmetrical coil can be reversed without

affecting performance.

(1) (2)

Controls

Flow

(2)

PC

(1)

Pressure

Controls

LE Specifications Performance Curves

Pressure Drop vs. Flow

Rated Flow 60 LPM (16 GPM)

PSI Bar Hydraulic Oil 150 SSU @ 100°F (32 cSt)

(At 70 PSI ∆∆ ∆∆ ∆P) 400 28.0

Elements

Logic

Solenoid

DC De-energized

Max. Pressure 6.9 - 276 Bar (100 - 4000 PSI) P)

300 21.0

Reseat Pressure 90% of Cracking Pressure

200 Hz PWM 200 14.0

Directional

Controls

MV Pressure Drop (

Max. Tank 70 Bar (1000 PSI)

Pressure 100 7.0

Cartridge Material All parts steel. All operating 0

Valves

Manual

parts hardened steel. LPM 15.2 30.3 45.0 60.0 76.0 90.0

SV 0

GPM 4 8 12 16 20 24

Flow (Q)

Operating Temp. -40°C to +93.3°C (Nitrile)

Range/Seals (-40°F to +200°F)

-31.7°C to +121.1°C (Fluorocarbon) Pressure Drop vs. Flow - Relieving Performance

Solenoid

Valves

(-25°F to +250°F) PSI Bar Hydraulic Oil 150 SSU @ 100°F (32 cSt)

PV 4000 280

Fluid Mineral-based or synthetic with

Compatibility/ lubricating properties at viscosities P) 3000 210

Viscosity of 45 to 2000 SSU (6 to 420 cSt)

Proportional

Valves

CE

Filtration ISO Code 16/13, 2000 140

SAE Class 4 or better Pressure Drop (

Approx. Weight .45 kg (.98 lbs.) 1000 70

Electronics

Coils &

Solenoid

Energized

BC

Cavity C10-2 0

(See BC Section for more details) LPM 0 15.2 30.3 45.0 60.0 76.0 90.0

GPM 4 8 12 16 20 24

Flow (Q)

Cavities

Bodies &

TD

Data

Technical

PC49 Parker Hannifin Corporation

Hydraulic Cartridge Systems