Page 47 - Parker - Hydraulic Cartidge System

P. 47

Catalog HY15-3502CPC/US

Technical Information Bodies and Cavities

CV

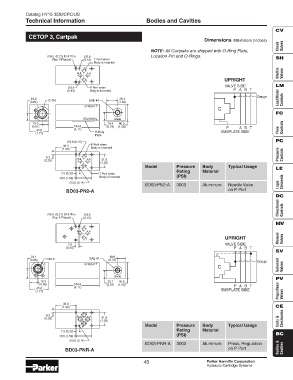

CETOP 3, Cartpak

Dimensions Millimeters (Inches)

Check Valves

NOTE: All Cartpaks are shipped with O-Ring Plate,

5.5 (0.21) Drill Thru 3.9 Location Pin and O-Rings. SH

(Typ. 4 Places) (0.15) T Port when

Body is Inverted

P

B A Shuttle Valves

UPRIGHT

T

VALVE SIDE LM

3.5 P Port when

(0.14) Body is Inverted P A BT

Gauge

16.2 C10-2 SAE #4 26.4 Load/Motor Controls

(0.64) (1.04)

C UPRIGHT

C

FC

GAGE

INVERTED

15.5 19.4 40.0

(0.61) 104.3 (0.76) (1.58) P A BT Controls

45.0 (4.11) Flow

(1.77) O-Ring SUBPLATE SIDE

Plate

PC

3.9 (0.15)

48.3 P Port when

(1.90) Body is Inverted

T Pressure Controls

6.3

(0.25) B A 31.8

(1.25)

Model Pressure Body Typical Usage

P LE

7.5 (0.30) T Port when Rating Material

40.5 (1.59) Body is Inverted (PSI)

3.5 (0.14) Elements

BD03-PN2-A 3000 Aluminum Needle Valve Logic

BD03-PN2-A on P Port

DC

Directional Controls

5.5 (0.21) Drill Thru 3.9

(Typ. 4 Places) (0.15)

MV

P

B A

UPRIGHT

T Manual Valves

7.5 VALVE SIDE

(0.30) PA BT

SV

24.1 18.6

(0.95) C10-3 SAE #4 (0.73) Gauge

C UPRIGHT Solenoid

C Valves

GAGE PV

19.3 20.7 40.0

(0.76) 104.3 (0.81) (1.58) PA BT

45.0 (4.11)

(1.77) SUBPLATE SIDE Proportional Valves

48.3

(1.90) CE

6.3 B T A

(0.25) 31.8 Electronics

(1.25) Coils &

Model Pressure Body Typical Usage

P

7.5 (0.30) Rating Material BC

40.5 (1.59) (PSI)

3.5 (0.14)

BD03-PNR-A 3000 Aluminum Press. Regulation

BD03-PNR-A on P Port Bodies & Cavities

45 Parker Hannifin Corporation

Hydraulic Cartridge Systems