Page 4 - Parker - Fulflo Honeycomb Filter Cartridges

P. 4

Fulfl o Honeycomb Cartridges

™

®

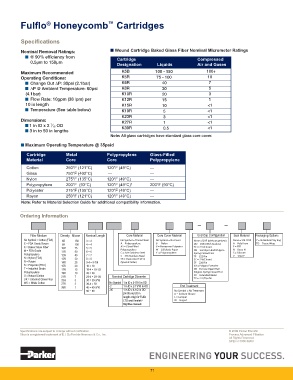

Specifi cations

Nominal Removal Ratings: n Wound Cartridge Baked Glass Fiber Nominal Micrometer Ratings

n @ 90% effi ciency from Cartridge Compressed

0.5µm to 150μm

Designation Liquids Air and Gases

Maximum Recommended K5B 100 - 150 100+

Operating Conditions: K5R 75 - 100 10

n Change Out P: 30psi (2.1bar) K6R 40 7

n P @ Ambient Temperature: 60psi K8R 30 5

(4.1bar) K10R 20 3

n Flow Rate: 10gpm (38 lpm) per K12R 15 1

10 in length K15R 10 <1

n Temperature (See table below) K19R 5 <1

K23R 3 <1

Dimensions: K27R 1 <1

7

n 1 in ID x 2 ⁄ 16 OD K39R 0.5 <1

n 3 in to 50 in lengths

Note: All glass cartridges have standard glass core cover.

n Maximum Operating Temperature @ 35psid

Cartridge Metal Polypropylene Glass-Filled

Material Core Core Polypropylene

Cotton 250°F (121°C) 120°F (49°C) —

Glass 750°F (402°C) — —

Nylon 275°F (135°C) 120°F (49°C) —

Polypropylene 200°F (93°C) 120°F (49°C) † 200°F (93°C)

Polyester 275°F (135°C) 120°F (49°C) —

Rayon 250°F (121°C) 120°F (49°C) —

Note: Refer to Material Selection Guide for additional compatibility information.

Ordering Information

– –

)LOWHU 0HGLXP 'HQVLW\ 0LFURQ 1RPLQDO /HQJWK &RUH 0DWHULDO &RUH &RYHU 0DWHULDO (QG &DS &RQ¿JXUDWLRQ 6HDO 0DWHULDO 3DFNDJLQJ 2SWLRQV

1R 6\PERO &RWWRQ )'$ 5 No Symbol = Tinned Steel No Symbol = No Cover None = DOE (without gaskets) None = Std. DOE Z = Individual Poly bag

( )'$ *UDGH 5D\RQ 5 A = Polypropylene B = Nylon DO = DOE (With Gaskets) A = Poly foam TIS = Tissue Wrap

. %DNHG *ODVV )LEHU 5 A3 = Glass-Filled V = Nonwoven Polyester TC = 222/Closed E = EPR

0 )'$ *UDGH 5 Polypropylene W = Cellulosic Paper OB = Std. Open End/Polypro N = Buna-N

3RO\SURS\OHQH 5 G = 304 Stainless Steel Y = Polypropylene Spring Closed End S = Silicone

S = 316 Stainless Steel

V = Viton®

1 1\ORQ )'$ 5 SR = Passivated 316 SS TF = 222/Fin

5 5D\RQ 5 (Special Order) SC = 226/Closed

SF = 226/Fin

6 3RO\HVWHU )'$ 5 XA = Polypro Extender

7 ,QGXVWULDO *UDGH 5 XB = Ex.Core Open End/

3RO\SURS\OHQH 5 Polypro Spring Closed End

8 1DWXUDO &RWWRQ 5 1RPLQDO &DUWULGJH 'LDPHWHU XC = Extended Metal

8. 8QEDNHG *ODVV )LEHU 5 TX = 222/Flex fin

:& :KLWH &RWWRQ 5 1R 6\PERO LQ ,' [ LQ 2'

5 LQ ,' [ LQ 2' (QG 7UHDWPHQW

LQ ,' [ LQ 2' No Symbol = No Treatment

DQG LQ D = Sodium Silicate

OHQJWK RQO\ IRU )XOIOR L = Lacquer

/7* DQG $PHWHN® M = Singed

%LJ %OXH 9HVVHOV

Specifi cations are subject to change without notifi cation. © 2009 Parker Hannifi n

Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc. Process Advanced Filtration

All Rights Reserved

SPEC-C1000 08/09

71