Page 2 - Parker - Fulflo ProBond Filter Cartridges

P. 2

™

®

Fulfl o ProBond Filter Cartridges

Specifi cations

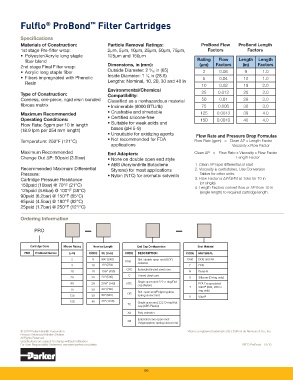

Materials of Construction: Particle Removal Ratings: ProBond Flow ProBond Length

1st stage Pre-fi lter wrap: 2μm, 5μm, 10μm, 25μm, 50μm, 75μm, Factors Factors

• Polyester/Acrylic long staple 125μm and 150μm

fi ber blend Rating Flow Length Length

Dimensions, in (mm): (μm) Factors (in) Factors

2nd stage Final Filter wrap:

9

Outside Diameter: 2 ⁄ 16 in (65)

• Acrylic long staple fi ber 1 2 0.08 9 1.0

• Fibers impregnated with Phenolic Inside Diameter: 1 ⁄ 8 in (28.6) 5 0.04 10 1.0

Lengths: Nominal, 10, 20, 30 and 40 in

Resin

10 0.02 19 2.0

Environmental/Chemical

Type of Construction: Compatibility: 25 0.012 20 2.0

Coreless, one-piece, rigid resin bonded Classifi ed as a nonhazardous material 50 0.01 29 3.0

fi brous matrix • Incinerable (8000 BTU/lb) 75 0.006 30 3.0

• Crushable and shredable

Maximum Recommended 125 0.0013 39 4.0

Operating Conditions: • Certifi ed silicone-free 150 0.0010 40 4.0

• Suitable for weak acids and

Flow Rate: 5gpm per 10 in length

(18.9 lpm per 254 mm length) bases (pH 5-9)

• Unsuitable for oxidizing agents Flow Rate and Pressure Drop Formulas

• Not recommended for FDA

Temperature: 250°F (121°C) Flow Rate (gpm) = Clean ΔP x Length Factor

applications Viscosity x Flow Factor

Maximum Recommended End Adapters: Clean ΔP = Flow Rate x Viscosity x Flow Factor

Change Out ΔP: 50psid (3.5bar) • None on double open end style Length Factor

• ABS (Acrylonitrile Butadiene 1. Clean ΔP ispsi differential at start.

Recommended Maximum Differential Styrene) for most applications 2. Viscosity is centistokes. Use Conversion

Pressure: • Nylon (NTC) for aromatic solvents Tables for other units.

Cartridge Pressure Resistance 3. Flow Factor is ΔP/GPM at 1cks for 10 in

150psid (10bar) @ 70°F (21°C) (or single).

4. Length Factors convert fl ow or ΔP from 10 in

125psid (8.6bar) @ 100°F (38°C) (single length) to required cartridge length.

90psid (6.2bar) @ 150°F (65°C)

65psid (4.5bar) @ 180°F (82°C)

25psid (1.7bar) @ 250°F (121°C)

Ordering Information

PRO — —

Cartridge Code Micron Rating Nominal Length End Cap Confi guration Seal Material

PRO ProBond Series (μm) CODE IN. (mm) CODE DESCRIPTION CODE MATERIAL

2 9 9¾" (248) Std. double open end (DOE) Omit DOE and XA

Omit coreless

5 10 10" (254) E EPR

CXC Extended tinned steel core

10 19 19½" (495) N Buna-N

C Tinned steel core

25 20 20" (508) S Silicone (O-ring only)

Single open end 222 o-ring/Flat

50 29 29¼" (743) NTC PFA Encapsulated

cap (Nylon) T Viton ® (222, 226 O-

75 30 30" (762) ring only)

Std. open end/Polypropylene

OB

125 39 39" (991) spring closed end V Viton ®

150 40 40" (1016) Single open end 222 O-ring/Flat

TC

cap (ABS Plastic)

XA Poly extender

Extended core open end/

XB

Polypropylene spring closed end

© 2010 Parker-Hannifi n Corporation Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc.

Process Advanced Filtration Division

All Rights Reserved

Specifi cations are subject to change without notifi cation

For User Responsibility Statement, see www.parker.com/safety SPEC-ProBond 01/10

66