Page 7 - Parker - Energy Products Division - Multitube (Instrument and Heat Trace Tubing Products)

P. 7

Chemical Processing and Refineries

Catalog Number 4200-M-2

Back to Table of Contents

How To Specify & Order

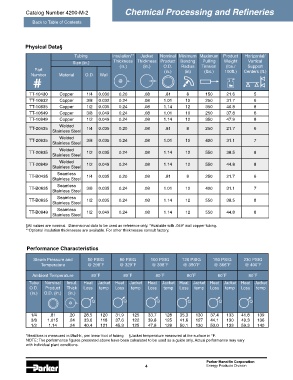

Physical Data§

Tubing Insulation** Jacket Nominal Minimum Maximum Product Horizontal/

Size (in.) Thickness Thickness Product Bendng Pulling Weight Vertical

(in.) (in.) O.D. Radius Tension (lbs./ Support

Part

(in.) (in) (lbs.) 100ft.) Centers (ft.)

Number Material O.D. Wall

lbs

TT-10430 Copper 1/4 0.030 0.20 .08 .81 8 150 21.6 5

TT-10632 Copper 3/8 0.032 0.24 .08 1.01 10 250 31.7 6

TT-10835 Copper 1/2 0.035 0.24 .08 1.14 12 350 40.8 8

TT-10649 Copper 3/8 0.049 0.24 .08 1.01 10 250 37.8 6

TT-10849 Copper 1/2 0.049 0.24 .08 1.14 12 350 47.9 8

Welded

TT-20435 1/4 0.035 0.20 .08 .81 8 250 21.7 6

Stainless Steel

Welded

TT-20635 3/8 0.035 0.24 .08 1.01 10 400 31.1 7

Stainless Steel

Welded

TT-20835 1/2 0.035 0.24 .08 1.14 12 550 38.5 8

Stainless Steel

Welded

TT-20849 1/2 0.049 0.24 .08 1.14 12 550 44.8 8

Stainless Steel

Seamless

TT-B0435 1/4 0.035 0.20 .08 .81 8 250 21.7 6

Stainless Steel

Seamless

TT-B0635 3/8 0.035 0.24 .08 1.01 10 400 31.1 7

Stainless Steel

Seamless

TT-B0835 1/2 0.035 0.24 .08 1.14 12 550 38.5 8

Stainless Steel

Seamless

TT-B0849 1/2 0.049 0.24 .08 1.14 12 550 44.8 8

Stainless Steel

§All values are nominal. Dimensional data to be used as reference only. *Available with .049" wall copper tubing.

**Optional insulation thicknesses are available. For other thicknesses consult factory.

Performance Characteristics

Steam Pressure and 50 PSIG 80 PSIG 100 PSIG 120 PSIG 150 PSIG 230 PSIG

Temperature @ 298˚F @ 329˚F @ 338˚F @ 350˚F @ 366˚F @ 400˚F

Ambient Temperature 80˚F 80˚F 80˚F 80˚F 80˚F 80˚F

Tube Nominal Insul. Heat Jacket Heat Jacket Heat Jacket Heat Jacket Heat Jacket Heat Jacket

O.D. Product Thick Loss temp Loss temp Loss temp Loss temp Loss temp Loss temp

(in.) O.D. (in.) (in.)

Q Q Q Q Q Q

1/4 .81 .20 28.5 120 31.9 125 33.7 128 35.3 130 37.4 133 41.8 139

3/8 1.015 .24 33.6 118 37.6 122 39.8 125 41.6 127 44.1 130 49.3 136

1/2 1.14 .24 40.4 121 45.3 125 47.8 128 50.1 130 53.0 133 59.3 140

*Heat loss is measured in Btu/Hr., per linear foot of tubing §Jacket temperature measured at the surface in °F.

NOTE: The performance figures presented above have been calculated to be used as a guide only. Actual performance may vary

with individual plant conditions.

Parker Hannifin Corporation

3 4 Energy Products Division