Page 2 - Parker - Fulflo TruBind 400 Cartridges

P. 2

®

Fulflo TruBind 400 Cartridges

Specifications Technology Performance

Unlike competitive technologies in which TruBind absorbent cartridge efficiency de-

Materials of Construction: hydrocarbons are removed through surface pends upon the residence time of the

Absorbent: Proprietary polymer adsorption onto the medium, TruBind fluid within the cartridge, which is a function

Support Construction: 100% polyolefin cartridges utilize a proprietary modified of the volumetric flow rate.

Seal Material: Polyethylene Foam polymer that both absorbs and chemically 1. Hydrocarbon Removal Efficiency: At

binds the hydrocarbon molecules into its in- an equivalent flow rate of 3.0 gpm per

Cartridge Dimensions (nominal) terior matrices. The affinity of the polymeric 10-inch cartridge the TruBind cartridge

Lengths: absorbent for hydrocarbon contaminant typically reduces trace hydrocarbon

9-13/16 in (249mm) is so great that accelerated testing by the contaminant in excess of 95% in single

19-15/16 in (506mm) Toxic Characteristics Leachate Procedure pass mode. This efficiency level can be

Outside Diameter: (TCLP) indicated the effluent hydrocar- maintained only to a net differential pres-

4-1/2 in (114 mm) bon level in water to be below current and sure of 10 psi. Series or multipass filtra-

Inside Diameter: proposed EPA limits. The modified polymer tion can virtually eliminate hydrocarbon

1-1/16 in (27 mm) was formulated to control the speed of contamination.

hydrocarbon absorption by eliminating the 2. Hydrocarbon Absorbent Capacity: The

Maximum Recommended Operating

potential for skin formation at the polymer/ TruBind cartridge medium has the poten-

Conditions:

Temperature: hydrocarbon interface. Consequently this tial to remove up to 500 grams (approxi-

150°F (65°C) @20 psid (1.4 bar); polymer, when incorporated into a radial- mately one pint) of low density hydro-

flow-design cartridge, insures maximum

carbon contaminant. On this basis, the

180°F (82°C) @10 psid (0.7 bar)

utilization of surface area. The nature of table below provides expected life data in

Pressure:

the polymer makes it an effective absor- hours or gallons at several trace contami-

40 psid (2.8 bar) @ 75°F (24°C)

Flow Rate: bent for free, emulsified and dissolved oils, nant levels based on a 3.0 gpm flow rate

3.0 gpm per 10-inch cartridge synthetic lubricants, grease and a multitude per 10-inch cartridge. Absorbent capacity

Changeout Pressure Drop (net): of organic solvents. will decrease as density of hydrocarbon

increases.

10 psi (0.7 bar)

Flow Factor: 3. Flow Rate Capability: A maximum

0.1 psid per 1 gpm at 1 cks viscosity flow rate of 3.0 gpm per 10-inch length

cartridge is recommended for the most

per 10 in cartridge

effective removal of trace hydrocarbon

pH Range: 2 - 12

contaminant.

BioSafety:

The TruBind cartridge is classified

as non-hazardous and incinerable.

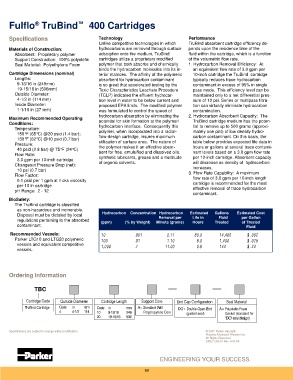

Disposal must be dictated by local Hydrocarbon Concentration Hydrocarbon Estimated Gallons Estimated Cost

Life in Fluid per Gallon

Removal per

regulations pertaining to the absorbed

(ppm) (% by Weight) Minute (grams) Hours Treated of Treated

contaminant. Fluid

Recommended Vessels: 10 .001 0.11 80.0 14,400 $ .002

Parker LTG10 and LTG20 polymeric 100 .01 1.10 8.0 1,400 $ .025

vessels and equivalent competitive 1,000 .1 11.00 0.8 144 $ .24

vessels.

Ordering Information

TBC

Cartridge Code Outside Diameter Cartridge Length Support Core Seal Material

TruBind Cartridge Code in mm Code in mm A = Standard Wall DO = Double-Open-End A

4 4-1/2 114 10 9-13/16 249 Polypropylene Core (gasket seal) Gasket (standard for

20 19-15/16 506 DO seal design)

Specifications are subject to change without notification. © 2007 Parker Hannafin

Process Advanced Filtration Inc.

All Rights Reserved

SPEC-C8510-Rev. A 01/08

ENGINEERING YOUR SUCCESS.

90