Page 30 - Parker - Fluoropolymer Extrusions

P. 30

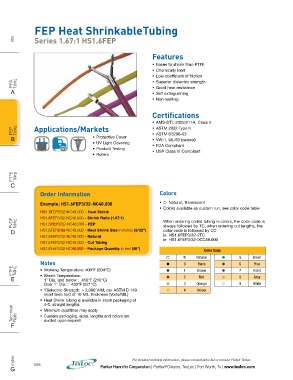

FEP Heat ShrinkableTubing

Intro Series 1.67:1 HS1.6FEP

Features

Easier to shrink than PTFE

Chemically inert

Low coefficient of friction

PFA Tubing Superior dielectric strength

Good heat resistance

A Self extinguishing

Non-wetting

Certifications

AMS-DTL-23053/11A, Class 2

FEP Tubing Applications/Markets ASTM 2902 Type II

ASTM D3296-03

B Protective Cover VW-1, UL-83 (natural)

UV Light Covering FDA Compliant

Product Testing USP Class VI Compliant

Rollers

PTFE Tubing

C

Order Information Colors

Example: HS1.6FEP3/32-NC48.000 Natural, Translucent

Colors available as custom run, see color code table

HS1.6FEP3/32-NC48.000 – Heat Shrink

PVDF Tubing HS1.6FEP3/32-NC48.000 – Shrink Ratio (1.67:1) When ordering coiled tubing in colors, the color code is

HS1.6FEP3/32-NC48.000 – FEP

always followed by TC; when ordering cut lengths, the

D HS1.6FEP3/32-NC48.000 – Heat Shrink Size in inches (3/32") color code is followed by CC

HS1.6FEP3/32-NC48.000 – Natural ie HS1.6FEP3/32-2TC

ie HS1.6FEP3/32-0CC48.000

HS1.6FEP3/32-NC48.000 – Cut Tubing

HS1.6FEP3/32-NC48.000 – Package Quantity in feet (48") Color Code

N Natural 5 Green

Notes 0 Black 6 Blue

ETFE Tubing Working Temperature: 400°F (204°C) 1 Brown 7 Violet

E Shrink Temperature: 2 Red 8 Gray

1" Dia. and below : 410°F (210°C)

Over 1" Dia. : 430°F (221°C) 3 Orange 9 White

*Dielectric Strength: > 2,000 V/M, per ASTM D 149 4 Yellow

short term test of 10 MIL thickness (Volts/MIL)

Heat Shrink tubing is available in stock packaging of

4-ft. straight lengths

Technical Pages Minimum quantities may apply

Custom packaging, sizes, lengths and colors are

F quoted upon request

Index B06 For detailed ordering information, please consult price list or contact Parker Texloc.

®

G Parker Hannifin Corporation | Parflex Division, TexLoc | Fort Worth, Tx | www.texloc.com