Page 2 - Parker - BVC floor mount

P. 2

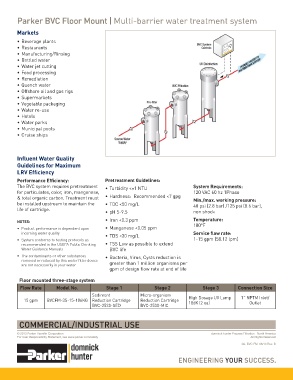

Parker BVC Floor Mount | Multi-barrier water treatment system

Markets

• Beverage plants

• Restaurants

• Manufacturing/Rinsing

• Bottled water

• Water jet cutting

• Food processing

• Remediation

• Quench water

• Offshore oil and gas rigs

• Supermarkets

• Vegetable packaging

• Water re-use

• Hotels

• Water parks

• Municipal pools

• Cruise ships

Infl uent Water Quality

Guidelines for Maximum

LRV Effi ciency

Performance Effi ciency: Pretreatment Guidelines:

The BVC system requires pretreatment System Requirements:

• Turbidity <=1 NTU

for particulates, color, iron, manganese, 120 VAC 60 hz 1Phase

• Hardness: Recommended <7 gpg

& total organic carbon. Treatment must Min./max. working pressure:

be installed upstream to maintain the • TOC <50 mg/L 40 psi (2.8 bar) /125 psi (8.6 bar),

life of cartridge.

• pH 5-9.5 non shock

• Iron <0.3 ppm Temperature:

NOTES:

100°F

• Product performance is dependent upon • Manganese <0.05 ppm

incoming water quality Service fl ow rate:

• TDS <30 mg/L

• System conforms to testing protocols as 1-15 gpm (58.12 lpm)

recommended in the USEPA Public Drinking • TSS Low as possible to extend

Water Guidance Manuals BVC life

• The contaminants or other substances • Bacteria, Virus, Cysts reduction is

removed or reduced by this water fi lter device

are not necessarily in your water greater than 1 million organisms per

gpm of design fl ow rate at end of life

Floor mounted three-stage system

Flow Rate Model No. Stage 1 Stage 2 Stage 3 Connection Size

Sediment Micro-organism

High Dosage UV Lamp 1˝ NPTM Inlet/

15 gpm BVCFM-3S-15-186KG Reduction Cartridge Reduction Cartridge 186K (2 ea) Outlet

BVC-2530-SED BVC-2530-MIC

COMMERCIAL/INDUSTRIAL USE

© 2013 Parker-Hannifi n Corporation domnick hunter Process Filtration - North America

For User Responsibility Statement, see www.parker.com/safety All Rights Reserved

GL_BVC FM 08/13 Rev. B