Page 2 - Parker - Fulflo XTL Filter cartridges

P. 2

®

Fulflo XTL Filter Cartridges

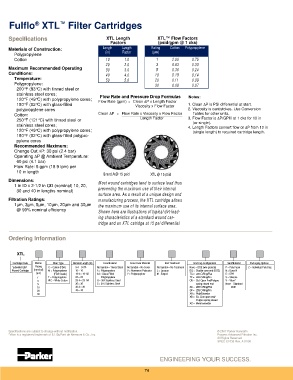

Specifications XTL Length XTL Flow Factors

Factors (psid/gpm @ 1 cks)

Materials of Construction: Length Length Rating Cotton Polypropylene

(µm)

Factor

(in)

Polypropylene

Cotton 10 1.0 1 2.00 0.75

20 2.0 3 0.63 0.33

Maximum Recommended Operating 30 3.0 5 0.36 0.24

Conditions: 40 4.0 10 0.19 0.14

Temperature: 50 5.0 20 0.11 0.09

Polypropylene:

30 0.09 0.07

200°F (93°C) with tinned steel or

stainless steel cores; Flow Rate and Pressure Drop Formulas Notes:

120°F (49°C) with polypropylene cores; Flow Rate (gpm) = Clean P x Length Factor

180°F (82°C) with glass-filled Viscosity x Flow Factor 1. Clean P is PSI differential at start.

polypropylene cores 2. Viscosity is centistokes. Use Conversion

Cotton: Clean P = Flow Rate x Viscosity x Flow Factor Tables for other units.

Length Factor 3. Flow Factor is P/GPM at 1 cks for 10 in

250°F (121°C) with tinned steel or (or single).

stainless steel cores; 4. Length Factors convert flow or P from 10 in

120°F (49°C) with polypropylene cores;

(single length) to required cartridge length.

180°F (82°C) with glass-filled polypro-

pylene cores

Recommended Maximum:

60 psi (4.1 bar)

Flow Rate: 5 gpm (18.9 lpm) per

10 in length

Brand A @ 15 psid XTL @ 15 psid

Dimensions: Most wound cartridges tend to surface load thus

1 in ID x 2-1/2 in OD (nominal) 10, 20,

preventing the maximum use of their internal

30 and 40 in lengths nominal)

surface area. As a result of a unique design and

Filtration Ratings: manufacturing process, the XTL cartridge allows

1µm, 3µm, 5µm, 10µm, 20µm and 30µm the maximum use of its internal surface area.

@ 90% nominal efficiency

Shown here are illustrations of typical dirt-load-

ing characteristics of a standard wound car-

tridge and an XTL catridge at 15 psi differential.

Ordering Information

XTL

Cartridge Code Micron Fiber Type Nominal Length (in) Core Material Core Cover Material End Treatment End Cap Configuration Seal Material Packaging Options

Extended Life Rating C = Cotton (FDA) 9-4 = 9-7/8 No Symbol = Tinned Steel No Symbol = No Cover No Symbol = No Treatment None = DOE (w/o gaskets) P = Poly Foam Z = Individual Poly Bag

Wound Cartridge (nominal) M = Polypropylene 10 = 10 A = Polypropylene V = Nonwoven Polyester L = Lacquer DO = Double open end (DOE) N = Buna-N

(µm) (FDA Grade) 19-4 = 19-1/2 A3 = Glass-Filled Y = Polypropylene M - Singed TC = 222 O-Ring/Flat E = EPR

1 T = Polypropylene 20 = 20 Polypropylene TF = 222 O-Ring/Fin S = Silicone

3 WC = White Cotton 29-4 = 29-1/4 G = 304 Stainless Steel OB = Std. Open End/Polypro V = Viton*

5 30 = 30 S = 316 Stainless Steel spring closed end None = Standard

10 39-4 = 39 SC = 226 O-Ring/Flat DOE

20 40 = 40 SF = 226 O-Ring/Fin

30 XA = Poly/Extender

XB = Ex. Core open end/

Polypro spring closed

XC = Metal extender

Specifications are subject to change without notification. © 2007 Parker Hannafin

*Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc. Process Advanced Filtration Inc.

All Rights Reserved

SPEC-C1030-Rev. A 01/08

ENGINEERING YOUR SUCCESS.

74