Page 2 - Parker - Proflow-HE

P. 2

Profl ow -HE

™

Pleated hydrophilic PTFE membrane and polypropylene supported cartridges

for microelectronic liquid

Specifi cations

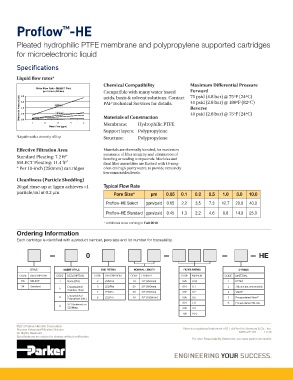

Liquid fl ow rates*

Chemical Compatibility Maximum Diff erential Pressure

Water Flow Rate - SELECT Pleat

per 10-inch (250 mm) Compatible with many water based Forward

70 psid (4.8 bar) @ 75ºF (24ºC)

8.0

Differential Pressure (psi) 6.0 0.05um PAF Technical Services for details. 40 psid (2.8 bar) @ 180ºF (82ºC)

acids, basis & solvent solutions. Contact

Reverse

4.0

40 psid (2.8 bar) @ 75ºF (24ºC)

0.1um

2.0

0.0

1 2 3 4 5 Materials of Construction

Hydrophilic PTFE

Membrane:

Water Flow (gpm)

Support layers: Polypropylene

*Liquids with a viscosity of 1 cp Structure: Polypropylene

Eff ective Filtration Area Materials are thermally bonded, for maximum

assurance of fi lter integrity and elimination of

Standard Pleating: 7.2 ft 2* bonding or sealing compounds. Modules and

SELECT Pleating: 11.4 ft 2* fi nal fi lter assemblies are fl ushed with 18-meg-

* Per 10-inch (250mm) cartridges ohm-cm high purity water, to provide extremely

low extractables levels.

Cleanliness (Particle Shedding)

20 gal rinse-up at 1gpm achieves <1 Typical Flow Rate

particle/ml at 0.2 μm

Pore Size* µm 0.05 0.1 0.2 0.5 1.0 3.0 10.0

Profl ow-HE Select gpm/psid 0.65 2.2 3.5 7.3 12.7 20.0 40.0

Profl ow-HE Standard gpm/psid 0.45 1.3 2.2 4.6 9.8 14.0 25.0

* Additional sizes coming in Fall 2010.

Ordering Information

Each cartridge is identifi ed with a product number, pore size and lot number for traceability.

— 0 — — — HE

STYLE INSERT STYLE END FITTING NOMINAL LENGTH FILTER RATING O-RINGS

CODE DESCRIPTION CODE DESCRIPTION CODE DESCRIPTION CODE LENGTH CODE MICRON CODE MATERIAL

PS SELECT 1 None (Std.) 2 226/Flat 10 10" (250mm) 925 0.05 1 EPDM

34 Standard Encapsulated 3 222/Flat 20 20" (500mm) 001 0.1 2 Silicone (recommended)

5

Stainless Steel

7 226/Fin 30 30" (750mm) 002 0.2 4 Viton ®

Encapsulated

6 8 222/Fin 40 40" (1000mm) 005 0.5 5 Encapsulated Viton ®

Polysulfone (Std.)

010 1.0 6 Encapsulated Silicone

½" Shortened on

A

222fi tting 030 3.0

100 10.0

©2010 Parker-Hannifi n Corporation

Process Advanced Filtration Division Viton is a registered trademark of E.I. duPont de Nemours & Co., Inc.

All Rights Reserved SPEC-PF-HE 11/10

Specifi cations are subject to change without notifi cation.

For User Responsibility Statement, see www.parker.com/safety