Page 4 - Parker - Oil and gas downstream applications filtration products for hydrocracking

P. 4

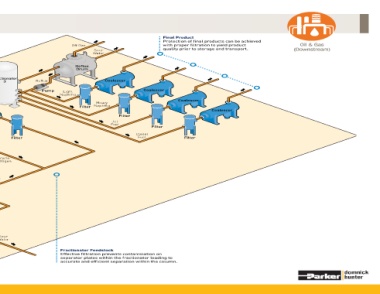

Oil & Gas (Downstream)

Protection of final products can be achieved

Coalescer

with proper filtration to yield product quality prior to storage and transport. Coalescer Filter

Final Product

Coalescer Filter

Diesel Fuel

Coalescer Filter Jet Fuel Effective filtration prevents contamination on separator plates within the fractionator leading to accurate and efficient separation within the column.

Sour Water Heavy Naphtha

Off Gas Reflux Drum Filter Fractionator Feedstock

Light Naphtha

Pump

Reflux

Fractionator 3 Filter Recycle Hydrogen Reactor Feed Sour Water

Coalescer Coalescer

Hydrogen Feed Heater

Sour Water Heat Exchanger Filter

Reactor Feed Gas to Amine Scrubber

Separator

Reactor 2 Hydrocracker Feedstock

Heater Reactor Feed

Recycle Hydrogen Reactor Feed Heat Exchanger Filter

Coalescer

Reactor 1 Hydrogen Feed

Pump Hydrocracker Feedstock

Recycle Hydrogen Filtration reduces scale build up in heat exchanger and heater for optimal heat transfer and protects the reactor catalyst to reduce energy and maintenance costs.

Hydrocracking

Process Overview