Page 2 - Parker - Fulflo HS Pleated Bag Filter

P. 2

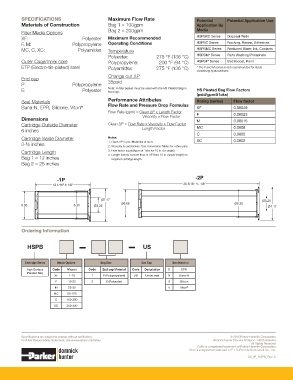

SPECIFICATIONS Maximum Flow Rate Potential Potential Application Use

Materials of Construction Bag 1 = 100gpm Application By

Bag 2 = 200gpm Media

Filter Media Options

HSPBXC Series Disposal Wells

XF: Polyester Maximum Recommended

F, M: Polypropylene Operating Conditions HSPBC Series Fracking, Resins, Adhesives

MC, C, XC: Polyamides Temperature HSPBMC Series Produced Water, Ink, Coolants

HSPBM* Series Parts Washing/Phosphate

Polyester: 275 °F (136 °C)

Outer Cage/Inner core Polypropylene: 200 °F (94 °C) HSPBF* Series Electrocoat, Paint

ETP (Electro-tin-plated) steel Polyamides: 275 °F (136 °C) * The F and M series is not recommended for fl uids

containing hydrocarbons

Change out ΔP

End cap

P: Polypropylene 35psid

E: Polyester Note: A fi lter basket must be used with the HS Pleated Bag in HS Pleated Bag Flow Factors

housings

(psid/gpm@1cks)

Seal Materials Performance Attributes Rating (series) Flow factor

Buna-N, EPR, Silicone, Viton ® Flow Rate and Pressure Drop Formulas XF 0.00049

Flow Rate (gpm) = Clean ΔP x Length Factor F 0.00023

Viscosity x Flow Factor

Dimensions M 0.00015

Cartridge Outside Diameter Clean ΔP = Flow Rate x Viscosity x Flow Factor

Length Factor MC 0.0008

6 inches

C 0.0005

Cartridge Inside Diameter Notes:

1. Clean ΔP is psi differential at start. XC 0.0002

3-¼ inches

2. Viscosity is centistokes. Use Conversion Tables for other units.

Cartridge Length 3. Flow factor is psid/gpm at 1cks for 10 in. (or single).

4. Length factors convert fl ow or ΔP from 10 in. (single length) to

Bag 1 = 12 inches required cartridge length.

Bag 2 = 26 inches

Ordering Information

HSPB — — US

Cartridge Series Media Options Bag Size End Cap Seal Material

High Surface Code Micron Code End cap Material Code Description E EPR

Pleated Bag

XF 1-10 1 P (Polypropylene) US Under seal N Buna-N

F 10-25 2 E (Polyester) S Silicon

M 25-50 V Viton ®

MC 50-100

C 100-200

XC 200-300

Specifi cations are subject to change without notifi cation. © 2015 Parker-Hannifi n Corporation

For User Responsibility Statement, see www.parker.com/safety domnick hunter Process Filtration - North America

All Rights Reserved

Fulfl o is a registered trademark of Parker-Hannifi n Corporation

Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc.

DS_IP_ HSPB_Rev. A