Page 42 - Mechatronics with Experiments

P. 42

JWST499-Cetinkunt

JWST499-c01

28 MECHATRONICS Printer: Yet to Come October 9, 2014 7:39 254mm×178mm

Lug

w cmd u T w eng

+ K fuel 1 T eng 1 eng 1

max

– p X u fuel X eng s+1 Js

Accelerator

Map Lug

Torque map

Engine controller Engine model

w eng

Sensor

(a)

Torque map

u fuel + T 1 T eng 1 w eng

f ()

1 Lug Limit eng s+1 Js

W

f ()

2

w eng

Engine model as torque source

(b)

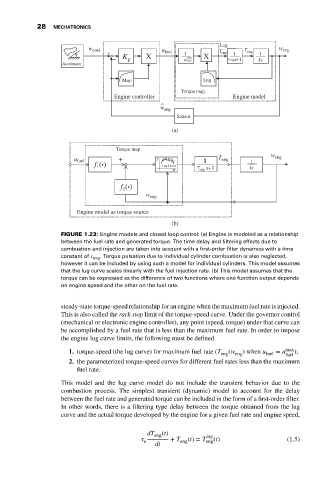

FIGURE 1.23: Engine models and closed loop control: (a) Engine is modeled as a relationship

between the fuel rate and generated torque. The time delay and filtering effects due to

combustion and injection are taken into account with a first-order filter dynamics with a time

constant of eng . Torque pulsation due to individual cylinder combustion is also neglected,

however it can be included by using such a model for individual cylinders. This model assumes

that the lug curve scales linearly with the fuel injection rate. (b) This model assumes that the

torque can be expressed as the difference of two functions where one function output depends

on engine speed and the other on the fuel rate.

steady-state torque-speed relationship for an engine when the maximum fuel rate is injected.

This is also called the rack stop limit of the torque-speed curve. Under the governor control

(mechanical or electronic engine controller), any point (speed, torque) under that curve can

be accomplished by a fuel rate that is less than the maximum fuel rate. In order to impose

the engine lug curve limits, the following must be defined

1. torque-speed (the lug curve) for maximum fuel rate (T (w ) when u = u max ),

eng eng fuel fuel

2. the parameterized torque-speed curves for different fuel rates less than the maximum

fuel rate.

This model and the lug curve model do not include the transient behavior due to the

combustion process. The simplest transient (dynamic) model to account for the delay

between the fuel rate and generated torque can be included in the form of a first-order filter.

In other words, there is a filtering type delay between the torque obtained from the lug

curve and the actual torque developed by the engine for a given fuel rate and engine speed,

dT eng (t)

lug

e + T eng (t) = T eng (t) (1.5)

dt