Page 499 - Mechatronics with Experiments

P. 499

Printer: Yet to Come

October 9, 2014 8:41 254mm×178mm

JWST499-c07

JWST499-Cetinkunt

ELECTROHYDRAULIC MOTION CONTROL SYSTEMS 485

Controller

DC P.S.

DSP

Amp

Cylinder

Valve

Pump

M/E

Motor/Engine

Reservoir

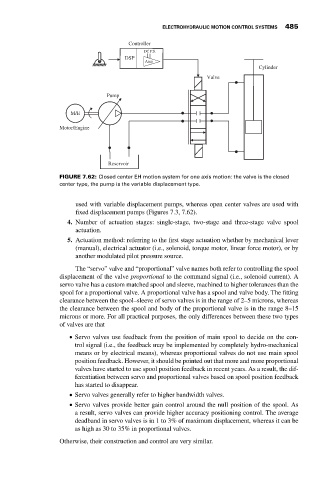

FIGURE 7.62: Closed center EH motion system for one axis motion: the valve is the closed

center type, the pump is the variable displacement type.

used with variable displacement pumps, whereas open center valves are used with

fixed displacement pumps (Figures 7.3, 7.62).

4. Number of actuation stages: single-stage, two-stage and three-stage valve spool

actuation.

5. Actuation method: referring to the first stage actuation whether by mechanical lever

(manual), electrical actuator (i.e., solenoid, torque motor, linear force motor), or by

another modulated pilot pressure source.

The “servo” valve and “proportional” valve names both refer to controlling the spool

displacement of the valve proportional to the command signal (i.e., solenoid current). A

servo valve has a custom matched spool and sleeve, machined to higher tolerances than the

spool for a proportional valve. A proportional valve has a spool and valve body. The fitting

clearance between the spool–sleeve of servo valves is in the range of 2–5 microns, whereas

the clearance between the spool and body of the proportional valve is in the range 8–15

microns or more. For all practical purposes, the only differences between these two types

of valves are that

Servo valves use feedback from the position of main spool to decide on the con-

trol signal (i.e., the feedback may be implemented by completely hydro-mechanical

means or by electrical means), whereas proportional valves do not use main spool

position feedback. However, it should be pointed out that more and more proportional

valves have started to use spool position feedback in recent years. As a result, the dif-

ferentiation between servo and proportional valves based on spool position feedback

has started to disappear.

Servo valves generally refer to higher bandwidth valves.

Servo valves provide better gain control around the null position of the spool. As

a result, servo valves can provide higher accuracy positioning control. The average

deadband in servo valves is in 1 to 3% of maximum displacement, whereas it can be

as high as 30 to 35% in proportional valves.

Otherwise, their construction and control are very similar.