Page 3 - Extraction and filtration technology for solder fumes and vapors_NA

P. 3

Technologies and emissions

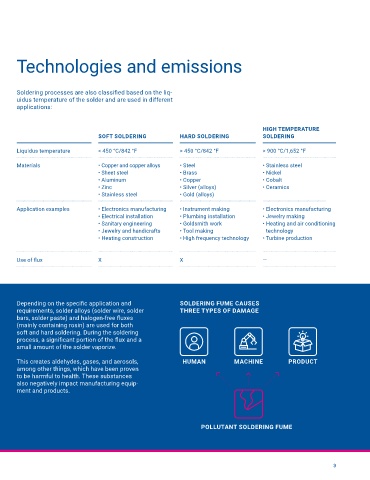

Soldering processes are also classified based on the liq-

uidus temperature of the solder and are used in different

applications:

HIGH TEMPERATURE

SOFT SOLDERING HARD SOLDERING SOLDERING

Liquidus temperature < 450 °C/842 °F > 450 °C/842 °F > 900 °C/1,652 °F

Materials • Copper and copper alloys • Steel • Stainless steel

• Sheet steel • Brass • Nickel

• Aluminum • Copper • Cobalt

• Zinc • Silver (alloys) • Ceramics

• Stainless steel • Gold (alloys)

Application examples • Electronics manufacturing • Instrument making • Electronics manufacturing

• Electrical installation • Plumbing installation • Jewelry making

• Sanitary engineering • Goldsmith work • Heating and air conditioning

• Jewelry and handicrafts • Tool making technology

• Heating construction • High frequency technology • Turbine production

Use of flux X X —

Depending on the specific application and SOLDERING FUME CAUSES

requirements, solder alloys (solder wire, solder THREE TYPES OF DAMAGE

bars, solder paste) and halogen-free fluxes

(mainly containing rosin) are used for both

soft and hard soldering. During the soldering

process, a significant portion of the flux and a

small amount of the solder vaporize.

This creates aldehydes, gases, and aerosols, HUMAN MACHINE PRODUCT

among other things, which have been proven

to be harmful to health. These substances

also negatively impact manufacturing equip-

ment and products.

POLLUTANT SOLDERING FUME

3