Page 4 - Extraction and filtration technology for solder fumes and vapors_NA

P. 4

Health risks and

legal basis

In North America, the primary federal agency responsible These regulations often differentiate between substanc-

for workplace air quality is the Occupational Safety and es based on their health risks, such as whether they

Health Administration (OSHA). OSHA sets standards for harm the brain, nerves, or respiratory system, and wheth-

permissible exposure limits (PELs) for various airborne er they can be inhaled deeply into the lungs.

contaminants. Additionally, the National Institute for

Occupational Safety and Health (NIOSH) recommends It’s essential for businesses to comply with all applicable

exposure limits (RELs) that are often more protective regulations to protect worker health and safety.

than PELs.

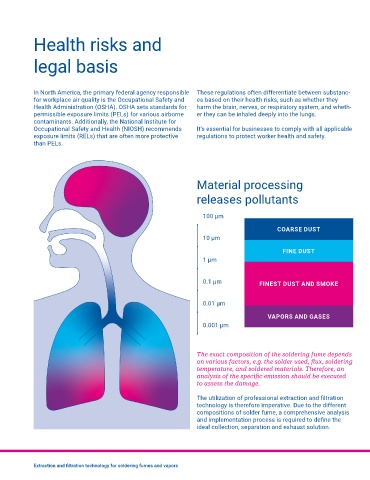

Material processing

releases pollutants

100 μm

COARSE DUST

10 μm

FINE DUST

1 μm

0.1 μm FINEST DUST AND SMOKE

0.01 μm

VAPORS AND GASES

0.001 μm

The exact composition of the soldering fume depends

on various factors, e.g. the solder used, flux, soldering

temperature, and soldered materials. Therefore, an

analysis of the specific emission should be executed

to assess the damage.

The utilization of professional extraction and filtration

technology is therefore imperative. Due to the different

compositions of solder fume, a comprehensive analysis

and implementation process is required to define the

ideal collection, separation and exhaust solution.

Extraction and filtration technology for soldering fumes and vapors 5