Page 46 - Australasian Paint & Panel March-April 2022

P. 46

PRODUCT FOCUS

46

PAINT&PANEL MARCH / APRIL 2022

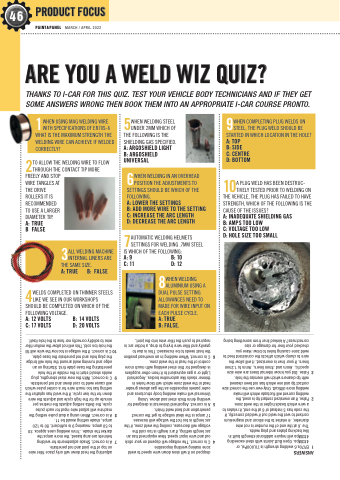

ARE YOU A WELD WIZ QUIZ?

THANKS TO I-CAR FOR THIS QUIZ. TEST YOUR VEHICLE BODY TECHNICIANS AND IF THEY GET SOME ANSWERS WRONG THEN BOOK THEM INTO AN APPROPRIATE I-CAR COURSE PRONTO.

1WHEN USING MAG WELDING WIRE WITH SPECIFICATIONS OF ER70S-6 WHAT IS THE MAXIMUM STRENGTH THE WELDING WIRE CAN ACHIEVE IF WELDED CORRECTLY?

2TO ALLOW THE THROUGH THE FREELY AND STOP WIRE TANGLES AT THE DRIVE ROLLERS IT IS RECOMMENDED TO USE A LARGER DIAMETER TIP.

A: TRUE

B FALSE

WELDING WIRE TO FLOW CONTACT TIP MORE

5WHEN WELDING STEEL UNDER 2MM WHICH OF THE FOLLOWING IS THE SHIELDING GAS SPECIFIED. A: ARGOSHIELD LIGHT B: ARGOSHIELD UNIVERSAL

4WELDS COMPLETED ON THINNER STEELS LIKE WE SEE IN OUR WORKSHOPS SHOULD BE COMPLETED ON WHICH OF THE FOLLOWING VOLTAGE.

A: 12 VOLTS B: 14 VOLTS C: 17 VOLTS D: 20 VOLTS

6WHEN WELDING IN AN OVERHEAD POSITION THE ADJUSTMENTS TO SETTINGS SHOULD BE WHICH OF THE FOLLOWING.

A: LOWER THE SETTINGS

B: ADD MORE WIRE TO THE SETTING C: INCREASE THE ARC LENGTH

D: DECREASE THE ARC LENGTH

7AUTOMATIC WELDING HELMETS SETTINGS FOR WELDING .7MM STEEL IS WHICH OF THE FOLLOWING:

A:9 B:10

TIVELY TESTED PRIOR TO WELDING ON THE VEHICLE, THE PLUG HAS FAILED TO HAVE STRENGTH, WHICH OF THE FOLLOWING IS THE CAUSE OF THE ISSUES?

A: INADEQUATE SHIELDING GAS

B: AMPS TOO LOW

C: VOLTAGE TOO LOW

D: HOLE SIZE TOO SMALL

9WHEN COMPLETING PLUG WELDS ON STEEL, THE PLUG WELD SHOULD BE STARTED IN WHICH LOCATION IN THE HOLE? A: TOP

B: SIDE

C: CENTRE D: BOTTOM

10

A PLUG WELD HAS BEEN DESTRUC-

3ALL WELDING MACHINE INTERNAL LINERS ARE THE SAME SIZE.

A: TRUE B: FALSE

C: 11

D: 12

8WHEN WELDING ALUMINIUM USING A DUAL PULSE SETTING ALLOWANCES NEED TO MADE FOR WIRE INPUT ON EACH PULSE CYCLE.

A: TRUE

B: FALSE.

ANSWERS

1 ER70s.6 welding strength is 70,000Psi, or

dropped on it will slow down wire speed to weld

adjusting the heat down will only place filler wire

483Mpa. Open Butt Joints with steel exceeding 483Mpa will require additional strength built in like backing plates and plug welds.

The .6 at the end of the number is not wire diameter, .6 relates to the silicon and magnesium content to wet the weld out if welded correctly, If the code has 3 instead of 6 at the end, it relates to a wire which beads higher in the weld zone.

zone making welding impossible.

4 C is correct. The voltage will depend on your stick

on top of the joint and not penetrate.

7 A is correct. Shade adjustments for welding helmets are amp based, the more amps the

2 False. If an oversized contact tip is used, the welding current will fluctuate which will make welding more difficult. Only ever use the correct size contact tip and one which has not been cleaned with tip cleaners which will oversize the hole.

welding 4mm thick steel and above. Using Universal will make welding body structures and outer panels impossible as the gas allows greater heat in the weld zone which will blow holes in thinner steels like automotive bodies. Argoshield Light or a gas equivalent to it from other suppliers is designed for thin steel welding with much more control of the heat in the weld zone.

9 C is correct. With the new steel strengths, plug welds should start in the middle of the hole penetrating the base plate first. Starting on an edge and running weld around the hole will bridge the plug hole and not penetrate the base plate.

3 False. Did you know internal liners are wire size specific, .6mm and .8mm liners, .9mm to 1.2mm liners. If your liner is oversized, it will allow the wire to clump which affects the consistent feed to weld zone causing holes to blow. Have you checked your liner for damage or size correctness? A kinked liner from something being

6 C is correct. When welding in an overhead position the heat needs to be increased. This is due to gravity and filler wire trying to drop, a hotter arc is required to push the filler wire into the joint,

10 C is correct. If the voltage is too low the wire will fill the hole too cold. This will not allow the molten filler wire to solidify correctly nor fuse to the hole itself.

out and wire input speed. New equipment has an arc length setting, if arc length is too cold the voltage will decrease, cooling the weld zone, if the arc length is too hot the voltage will increase.

darker the shade. .7mm welding uses approx. 30 to 50 amps. meaning 9 is sufficient. 80 to 120 amps, shade setting would be 11.

17 amps is the ideal voltage to get the correct

8 A is correct. When using a dual pulse setting the machine will adjust wire input for each pulse cycle, the Delta setting adjusts the metres per minute up for the high cycle and adjusts the wire down for the low cycle. If the weld has splatter the setting has too much wire for a colder pulse which will cause weld to cool down and not penetrate.

penetration and best weld finish.

5 A is correct. Argoshield Universal is designed for