Page 234 - Icon Ridge Hardware & Fixing Technology Catalog

P. 234

Fixing technology

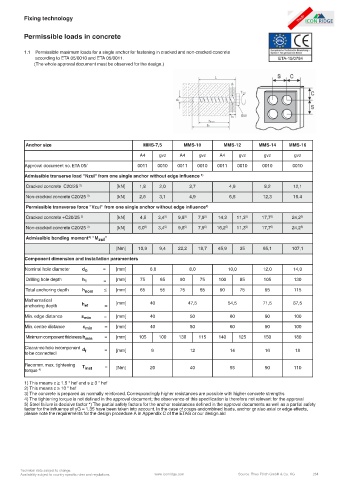

Permissible loads in concrete

1.1 Permissible maximum loads for a single anchor for fastening in cracked and non-cracked concrete

according to ETA 05/0010 and ETA 05/0011.

(The whole approval document must be observed for the design.)

Anchor size MMS-7,5 MMS-10 MMS-12 MMS-14 MMS-16

A4 gvz A4 gvz A4 gvz gvz gvz

Approval document no. ETA 05/ 0011 0010 0011 0010 0011 0010 0010 0010

Admissible transerse load "Nzul" from one single anchor without edge influence 1)

Cracked concrete C20/25 3) [kN] 1,8 2,0 3,7 4,9 8,2 12,1

Non-cracked concrete C20/25 3) [kN] 2,6 3,1 4,9 6,5 12,3 16.4

Permissible transverse force "Vzul" from one single anchor without edge influence 2)

Cracked concrete +C20/25 3) [kN] 4,5 3,4 5) 9,8 5) 7,9 5) 14,3 11,3 5) 17,7 5) 24,2 5)

Non-cracked concrete C20/25 3) [kN] 6,0 5) 3,4 5) 9,8 5) 7,9 5) 16,2 5) 11,3 5) 17,7 5) 24,2 5)

)

Admissible bending moment* "M zul "

[Nm] 10,9 9,4 22,2 18,7 45,9 35 65,1 107,1

Component dimension and installation paramenters

Nominal hole diameter d O = [mm] 6,0 8,0 10,0 12,0 14,0

Drilling hole depth h 1 = [mm] 75 65 90 75 100 85 105 130

Total anchoring depth h nom < [mm] 65 55 75 65 90 75 95 115

Mathematical [mm] 40 47,5 54,5 71,5 87,5

anchoring depth h ef =

Min. edge distance s = [mm] 40 50 60 90 100

min

Min. centre distance c min = [mm] 40 50 60 90 100

Minimum component thickness h min = [mm] 105 100 130 115 140 125 150 180

Clearance hole incomponent d = [mm] 9 12 14 16 18

to be connectedl f

Recomm. max. tightening T =

torque 4) inst [Nm] 20 40 55 90 110

1) This means c ≥ 1.5 * hef and s ≥ 3 * hef

2) This means c ≥ 10 * hef

3) The concrete is prepared as normally reinforced. Correspondingly higher resistances are possible with higher concrete strengths

4) The tightening torque is not defined in the approval document; the observance of this specification is therefore not relevant for the approval

5) Steel failure is decisive factor *) The partial safety factors for the anchor resistances defined in the approval documents as well as a partial safety

factor for the influence of γG = 1.35 have been taken into account. In the case of coups andombined loads, anchor gr also axial or edge effects,

please note the requirements for the design procedure A in Appendix C of the ETAG or our design aid

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 234