Page 365 - Icon Ridge Hardware & Fixing Technology Catalog

P. 365

Chemical products for construction

General usage instructions for sealants:

Silicone sealant base:

Our single component silicone sealants harden under the influence of air humidity and have the following properties:

High elasticity level, in accordance with EN 26927

Good bonding properties

Sealed and easy-to-clean surface

High resistance to weather and geing

Good UV resistance

And temperature resistance of at least 160 °C

The silicone sealants cannot be painted over or varnished. The silicone sealants are designed for sealing expansion connection and movement

joints and are used in the most varied areas of applications.

Due to the variety of possible applications, the sealant should be tested in each individual usage case to ensure that it is suitable and effective.

Silicone sealant compounds (excluding silicone MC) contain plasticisers. If the sealant comes into contact with materials that tend to absorb or

release plasticisers, damage may be caused to the sealant or substrate. Products of this nature include some soft synthetic materials, strips of

synthetic material, adhesive tapes, other sealants, tar, bitumen, etc. With marble, sandstone, and similarly absorptive, sensitive substrates the

edge zones may become soiled. Joints affected by mechanical factors, chemicals, or severe moisture are maintenance joints according to DIN

52460.

1. Substrate:

The surfaces contacting the sealant must be sustainable, dry, and clean, free from dust, dirt, rust, oil, and similar materials.

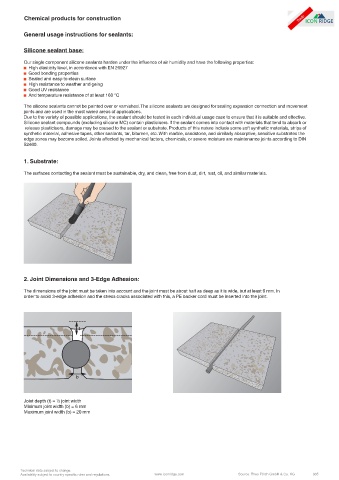

2. Joint Dimensions and 3-Edge Adhesion:

The dimensions of the joint must be taken into account and the joint must be about half as deep as it is wide, but at least 6 mm. In

order to avoid 3-edge adhesion and the stress cracks associated with this, a PE backer cord must be inserted into the joint.

t

b

Joint depth (t) = ½ joint width

Minimum joint width (b) = 6 mm

Maximum joint width (b) = 20 mm

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 365