Page 434 - Icon Ridge Maintenance & Service Catalog

P. 434

Cutting, Sanding, Sawing, Surface Treatment

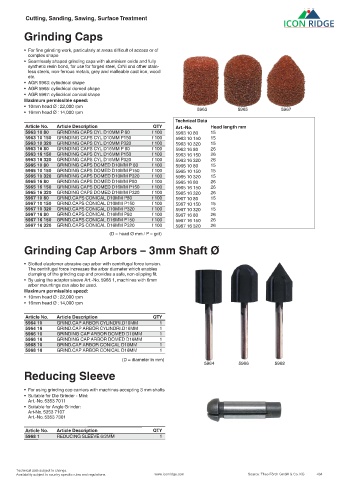

Grinding Caps

• For fine grinding work, particularly at areas difficult of access or of

complex shape

• Seamlessly shaped grinding caps with aluminium oxide and fully

synthetic resin bond, for use for forged steel, CrNi and other stain-

less steels, non-ferrous metals, grey and malleable cast iron, wood

etc.

• AGR 5963: cylindrical shape

• AGR 5965: cylindrical domed shape

• AGR 5967: cylindrical conical shape

Maximum permissible speed:

• 10mm head Ø : 22,000 rpm

5963 5965 5967

• 16mm head Ø : 14,000 rpm

Technical Data

Article No. Article Description QTY Art.-No. Head length mm

5963 10 80 GRINDING CAPS CYL D10MM P 80 f 100 5963 10 80 15

5963 10 150 GRINDING CAPS CYL D10MM P150 f 100 5963 10 150 15

5963 10 320 GRINDING CAPS CYL D10MM P320 f 100 5963 10 320 15

5963 16 80 GRINDING CAPS CYL D16MM P 80 f 100 5963 16 80 26

5963 16 150 GRINDING CAPS CYL D16MM P150 f 100 5963 16 150 26

5963 16 320 GRINDING CAPS CYL D16MM P320 f 100 5963 16 320 26

5965 10 80 GRINDING CAPS DOMED D10MM P 80 f 100 5965 10 80 15

5965 10 150 GRINDING CAPS DOMED D10MM P150 f 100 5965 10 150 15

5965 10 320 GRINDING CAPS DOMED D10MM P320 f 100 5965 10 320 15

5965 16 80 GRINDING CAPS DOMED D16MM P80 f 100 5965 16 80 26

5965 16 150 GRINDING CAPS DOMED D16MM P150 f 100 5965 16 150 26

5965 16 320 GRINDING CAPS DOMED D16MM P320 f 100 5965 16 320 26

5967 10 80 GRIND.CAPS CONICAL D10MM P80 f 100 5967 10 80 15

5967 10 150 GRIND.CAPS CONICAL D10MM P150 f 100 5967 10 150 15

5967 10 320 GRIND.CAPS CONICAL D10MM P320 f 100 5967 10 320 15

5967 16 80 GRIND.CAPS CONICAL D16MM P80 f 100 5967 16 80 26

5967 16 150 GRIND.CAPS CONICAL D16MM P150 f 100 5967 16 150 26

5967 16 320 GRIND.CAPS CONICAL D16MM P320 f 100 5967 16 320 26

(D = head Ø mm / P = grit)

Grinding Cap Arbors – 3mm Shaft Ø

• Slotted elastomer abrasive cap arbor with centrifugal force tension.

The centrifugal force increases the arbor diameter which enables

clamping of the grinding cap and provides a safe, non-slipping fit.

• By using the adapter sleeve Art.-No. 5968 1, machines with 6mm

arbor mountings can also be used.

Maximum permissible speed:

• 10mm head Ø : 22,000 rpm

• 16mm head Ø : 14,000 rpm

Article No. Article Description QTY

5964 10 GRIND.CAP ARBOR CYLINDRI.D10MM 1

5964 16 GRIND.CAP ARBOR CYLINDRI.D16MM 1

5966 10 GRINDING CAP ARBOR DOMED D10MM 1

5966 16 GRINDING CAP ARBOR DOMED D16MM 1

5968 10 GRIND.CAP ARBOR CONICAL D10MM 1

5968 16 GRIND.CAP ARBOR CONICAL D16MM 1

(D = diameter in mm)

5964 5966 5968

Reducing Sleeve

• For using grinding cap carriers with machines accepting 3 mm shafts

• Suitable for Die Grinder - Mini:

Art.-No. 5353 7011

• Suitable for Angle Grinder:

Art-No. 5353 7107

Art.-No. 5353 7301

Article No. Article Description QTY

5968 1 REDUCING SLEEVE 6/3MM 1

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 434