Page 234 - Icon Ridge Industrial Tools Catalog

P. 234

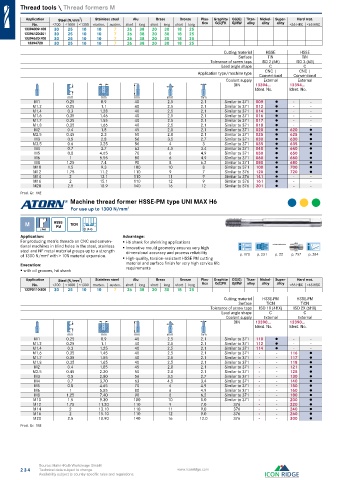

Thread tools \ Thread formers M

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13394009-100 30 25 10 10 7 26 38 20 30 18 25

13394120-201 30 25 10 10 7 26 38 20 30 18 25

13394620-700 30 25 10 10 7 26 38 20 30 18 25

13394720 30 25 10 10 7 26 38 20 30 18 25

Cutting material HSSE HSSE

Surface TiN TiN

Tolerance of screw taps ISO 2 (6H) ISO 3 (6G)

Lead angle shape C C

CNC |

CNC |

Application type/machine type Conventional Conventional

Coolant supply External External

DIN 13394... 13394...

Ident. No. Ident. No.

mm mm mm mm mm

M1 0.25 0.9 40 2.5 2.1 Similar to 371 009 ● - -

M1.2 0.25 1.1 40 2.5 2.1 Similar to 371 012 ● - -

M1.4 0.3 1.28 40 2.5 2.1 Similar to 371 014 ● - -

M1.6 0.35 1.46 40 2.5 2.1 Similar to 371 016 ● - -

M1.7 0.35 1.55 40 2.5 2.1 Similar to 371 017 ● - -

M1.8 0.35 1.66 40 2.5 2.1 Similar to 371 018 ● - -

M2 0.4 1.8 45 2.8 2.1 Similar to 371 020 ● 620 ●

M2.5 0.45 2.3 50 2.8 2.1 Similar to 371 025 ● 625 ●

M3 0.5 2.8 56 3.5 2.7 Similar to 371 030 ● 630 ●

M3.5 0.6 3.25 56 4 3 Similar to 371 035 ● 635 ●

M4 0.7 3.7 63 4.5 3.4 Similar to 371 040 ● 640 ●

M5 0.8 4.65 70 6 4.9 Similar to 371 050 ● 650 ●

M6 1 5.55 80 6 4.9 Similar to 371 060 ● 660 ●

M8 1.25 7.4 90 8 6.2 Similar to 371 080 ● 680 ●

M10 1.5 9.3 100 10 8 Similar to 371 100 ● 700 ●

M12 1.75 11.2 110 9 7 Similar to 376 120 ● 720 ●

M14 2 13.1 110 11 9 Similar to 376 141 ● - -

M16 2 15.1 110 12 9 Similar to 376 161 ● - -

M20 2.5 18.9 140 16 12 Similar to 376 201 ● - -

Prod. Gr. 1KE

Machine thread former HSSE-PM type UNI MAX H6

For use up to 1300 N/mm 2

M HSSE- TiCN

3xd PM C (2-3)

Application: Advantage:

For producing metric threads on CNC and conven- H6 shank for shrinking applications

tional machines in blind holes in the steel, stainless Innovative mould geometry ensures very high

steel and NF metal material groups up to a strength dimensional accuracy and process reliability

of 1300 N/mm with > 10% material expansion. p. 170 p. 231 p. 22 p. 757 p. 284

2

High-quality, torsion-resistant HSSE PM cutting

Execution: material and surface finish for very high service life

with oil grooves, h6 shank requirements

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13390110-300 30 25 10 10 7 26 38 20 30 18 25

Cutting material HSSE-PM HSSE-PM

Surface TiCN TiCN

Tolerance of screw taps ISO 1X (4HX) ISO 2X (6HX)

Lead angle shape C C

Coolant supply External External

DIN 13390... 13390...

Ident. No. Ident. No.

mm mm mm mm mm

M1 0.25 0.9 40 2.5 2.1 Similar to 371 110 ● - -

M1.2 0.25 1.1 40 2.5 2.1 Similar to 371 112 ● - -

M1.4 0.3 1.25 40 2.5 2.1 Similar to 371 114 ● - -

M1.6 0.35 1.45 40 2.5 2.1 Similar to 371 - - 116 ●

M1.7 0.35 1.55 40 2.5 2.1 Similar to 371 - - 117 ●

M1.8 0.35 1.65 40 2.5 2.1 Similar to 371 - - 118 ●

M2 0.4 1.85 45 2.8 2.1 Similar to 371 - - 121 ●

M2.5 0.45 2.30 50 2.8 2.1 Similar to 371 - - 125 ●

M3 0.5 2.80 56 3.5 2.7 Similar to 371 - - 130 ●

M4 0.7 3.70 63 4.5 3.4 Similar to 371 - - 140 ●

M5 0.8 4.65 70 6 4.9 Similar to 371 - - 150 ●

M6 1 5.55 80 6 4.9 Similar to 371 - - 160 ●

M8 1.25 7.40 90 8 6.2 Similar to 371 - - 180 ●

M10 1.5 9.30 100 10 8.0 Similar to 371 - - 200 ●

M12 1.75 11.20 110 9 7.0 376 - - 220 ●

M14 2 13.10 110 11 9.0 376 - - 240 ●

M16 2 15.10 110 12 9.0 376 - - 260 ●

M20 2.5 18.90 140 16 12.0 376 - - 300 ●

Prod. Gr. 1KE

Source: Hahn+Kolb Werkzeuge GmbH

234 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.