Page 239 - Icon Ridge Industrial Tools Catalog

P. 239

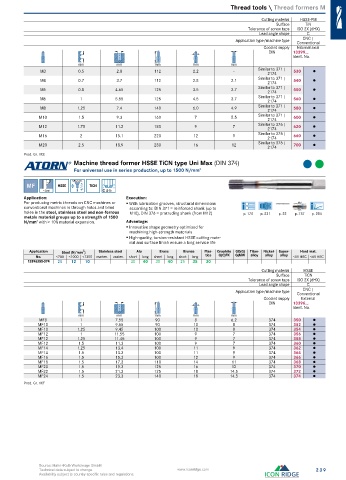

Thread tools \ Thread formers M

Cutting material HSSE-PM

Surface TiN

Tolerance of screw taps ISO 2X (6HX)

Lead angle shape C

CNC |

Application type/machine type Conventional

Coolant supply Internal axial

DIN 13399...

Ident. No.

mm mm mm mm mm

M3 0.5 2.8 112 2.2 - Similar to 371 | 530 ●

2174

M4 0.7 3.7 112 2.8 2.1 Similar to 371 | 540 ●

2174

M5 0.8 4.65 125 3.5 2.7 Similar to 371 | 550 ●

2174

M6 1 5.55 125 4.5 3.7 Similar to 371 | 560 ●

2174

M8 1.25 7.4 140 6.0 4.9 Similar to 371 | 580 ●

2174

M10 1.5 9.3 160 7 5.5 Similar to 371 | 600 ●

2174

M12 1.75 11.2 180 9 7 Similar to 376 | 620 ●

2174

M16 2 15.1 220 12 9 Similar to 376 | 660 ●

2174

M20 2.5 18.9 280 16 12 Similar to 376 | 700 ●

2174

Prod. Gr. 1KE

Machine thread former HSSE TiCN type Uni Max (DIN 374)

For universal use in series production, up to 1500 N/mm

2

CNC/conv.

MF HSSE TiCN

3xd C (2-3)

Application: Execution:

For producing metric threads on CNC machines or With lubrication grooves, structural dimensions

conventional machines in through holes and blind according to: DIN 371 = reinforced shank (up to

holes in the steel, stainless steel and non-ferrous M10), DIN 376 = protruding shank (from M12) p. 170 p. 231 p. 22 p. 757 p. 284

metals material groups up to a strength of 1500

N/mm with > 10% material expansion. Advantage:

2

Innovative shape geometry optimised for

machining high-strength materials

High-quality, torsion-resistant HSSE cutting mate-

rial and surface finish ensure a long service life

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13396350-374 28 12 10 30 40 30 40 25 35 30

Cutting material HSSE

Surface TiCN

Tolerance of screw taps ISO 2X (6HX)

Lead angle shape C

CNC |

Application type/machine type Conventional

Coolant supply External

DIN 13396...

Ident. No.

mm mm mm mm mm

MF8 1 7.55 90 8 6.2 374 350 ●

MF10 1 9.55 90 10 8 374 352 ●

MF10 1.25 9.45 100 10 8 374 354 ●

MF12 1 11.55 100 9 7 374 356 ●

MF12 1.25 11.45 100 9 7 374 358 ●

MF12 1.5 11.3 100 9 7 374 360 ●

MF14 1.25 13.4 100 11 9 374 362 ●

MF14 1.5 13.3 100 11 9 374 364 ●

MF16 1.5 15.3 100 12 9 374 366 ●

MF18 1.5 17.3 110 14 11 374 368 ●

MF20 1.5 19.3 125 16 12 374 370 ●

MF22 1.5 21.3 125 18 14.5 374 372 ●

MF24 1.5 23.3 140 18 14.5 374 374 ●

Prod. Gr. 1KF

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 239

Availability subject to country specific rules and regulations.