Page 245 - Icon Ridge Industrial Tools Catalog

P. 245

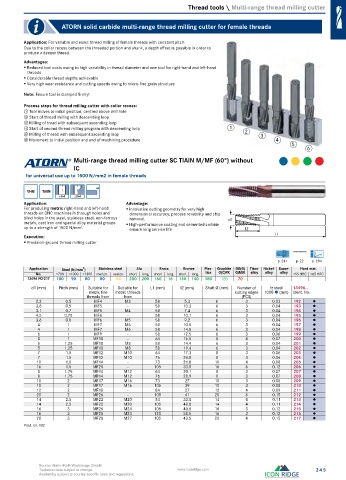

Thread tools \ Multi-range thread milling cutter

ATORN solid carbide multi-range thread milling cutter for female threads

Application: For variable and exact thread milling of female threads with constant pitch.

Due to the collar recess between the threaded portion and shank, a depth offset is possible in order to

produce a deeper thread.

Advantages:

Reduced tool costs owing to high variability in thread diameter and one tool for right-hand and left-hand

threads

Considerable thread depths achievable

Very high wear resistance and cutting speeds owing to micro-fine grain structure

Note: Ensure tool is clamped firmly!

Process steps for thread milling cutter with collar recess:

① Tool moves to initial position, centred above drill hole

③ Start of thread milling with descending loop

③ Milling of tread with subsequent ascending loop

④ Start of second thread milling program with descending loop 1 2

⑤ Milling of thread with subsequent ascending loop 3

⑥ Movement to initial position and end of machining procedure 4

5

6

Multi-range thread milling cutter SC TIAlN M/MF (60°) without

IC

for universal use up to 1500 N/mm2 in female threads

HA

VHM TiAlN

3xd 2xd

Application: Advantage:

For producing metric right-hand and left-hand Innovative cutting geometry for very high

threads on CNC machines in through holes and dimensional accuracy, process reliability and chip

blind holes in the steel, stainless steel, non-ferrous removal. d1

metals, cast iron and special alloy material groups High-performance coating and cemented carbide

up to a strength of 1500 N/mm . 2 ensure long service life l2

Execution: l1

Precision-ground thread milling cutter

p. 241 p. 22 p. 284

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13496192-217 100 90 80 80 60 200 200 160 16 140 140 180 120 70

d1 (mm) Pitch (mm) Suitable for Suitable for L1 (mm) l2 (mm) Shaft Ø (mm) Number of fz steel 13496...

metric fine metric threads cutting edges 1000 (mm) Ident. No.

threads from from (PCS)

2.2 0.5 MF4 M3 58 5.3 6 3 0.03 192 ●

3.8 0.5 MF5 - 58 10.3 6 3 0.04 193 ●

3.1 0.7 MF5 M4 58 7.4 6 3 0.04 194 ●

4.5 0.75 MF6 - 58 10.1 6 3 0.04 195 ●

3.6 0.8 MF6 M5 58 9.2 6 3 0.04 196 ●

4 1 MF7 M6 58 10.5 6 3 0.04 197 ●

4 1 MF7 M6 58 14.5 6 3 0.04 198 ●

6 1 MF9 - 58 12.5 6 3 0.06 199 ●

8 1 MF10 - 64 16.5 8 4 0.07 200 ●

5 1.25 MF10 M8 58 14.4 6 3 0.04 201 ●

5 1.25 MF10 M8 58 19.4 6 3 0.04 202 ●

7 1.5 MF12 M10 64 17.3 8 3 0.06 203 ●

7 1.5 MF12 M10 76 24.8 8 3 0.06 204 ●

10 1.5 MF14 - 73 21.8 10 4 0.08 205 ●

16 1.5 MF20 - 105 33.8 16 6 0.12 206 ●

8 1.75 MF14 M12 64 20.1 8 3 0.07 207 ●

8 1.75 MF14 M12 76 28.9 8 3 0.07 208 ●

10 2 MF17 M16 73 27 10 3 0.08 209 ●

10 2 MF17 M16 105 39 10 3 0.08 210 ●

12 2 MF18 - 84 27 12 4 0.09 211 ●

20 2 MF26 - 105 41 20 6 0.15 212 ●

14 2.5 MF22 M20 84 33.8 14 4 0.11 213 ●

14 2.5 MF22 M20 105 48.8 14 4 0.11 214 ●

16 3 MF25 M24 105 40.5 16 3 0.12 215 ●

16 3 MF25 M24 120 58.5 16 3 0.12 216 ●

20 3 MF28 M27 105 43.5 20 4 0.15 217 ●

Prod. Gr. 132

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 245

Availability subject to country specific rules and regulations.