Page 257 - Icon Ridge Industrial Tools Catalog

P. 257

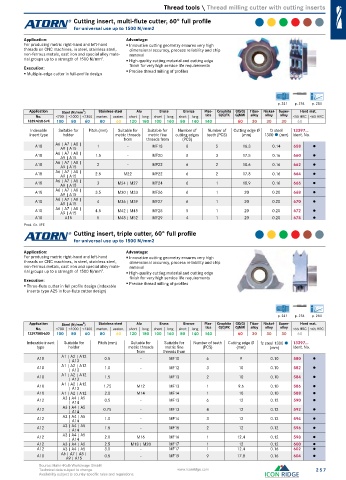

Thread tools \ Thread milling cutter with cutting inserts

Cutting insert, multi-flute cutter, 60° full profile

for universal use up to 1500 N/mm2

Application: Advantage:

For producing metric right-hand and left-hand Innovative cutting geometry ensures very high

threads on CNC machines, in steel, stainless steel, dimensional accuracy, process reliability and chip

non-ferrous metals, cast iron and special alloy mate- removal

rial groups up to a strength of 1500 N/mm . 2 High-quality cutting material and cutting edge

finish for very high service life requirements

Execution: Precise thread milling of profiles

Multiple-edge cutter in full-profile design

p. 241 p. 254 p. 284

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13397658-674 100 80 60 80 60 120 180 100 160 80 140 140 60 30 30 30 60

Indexable Suitable for Pitch (mm) Suitable for Suitable for Number of Number of Cutting edge Ø fz steel 13397...

insert type holder metric threads metric fine cutting edges teeth (PCS) (mm) 1300 (mm) Ident. No.

from threads from (PCS)

A18 A6 | A7 | A8 | 1 - MF18 8 5 16.3 0.14 658 ●

A9 | A15

A18 A6 | A7 | A8 | 1.5 - MF20 8 3 17.5 0.16 660 ●

A9 | A15

A18 A6 | A7 | A8 | 2 - MF22 6 2 18.6 0.16 662 ●

A9 | A15

A18 A6 | A7 | A8 | 2.5 M22 MF22 6 2 17.8 0.16 664 ●

A9 | A15

A18 A6 | A7 | A8 | 3 M24 | M27 MF24 6 1 18.9 0.16 666 ●

A9 | A15

A18 A6 | A7 | A8 | 3.5 M30 | M33 MF26 6 1 20 0.20 668 ●

A9 | A15

A18 A6 | A7 | A8 | 4 M36 | M39 MF27 6 1 20 0.20 670 ●

A9 | A15

A18 A6 | A7 | A8 | 4.5 M42 | M45 MF28 5 1 20 0.20 672 ●

A9 | A15

A18 A15 5 M48 | M52 MF29 4 1 20 0.20 674 ●

Prod. Gr. 1FE

Cutting insert, triple cutter, 60° full profile

for universal use up to 1500 N/mm2

Application: Advantage:

For producing metric right-hand and left-hand Innovative cutting geometry ensures very high

threads on CNC machines, in steel, stainless steel, dimensional accuracy, process reliability and chip

non-ferrous metals, cast iron and special alloy mate- removal

rial groups up to a strength of 1500 N/mm . 2 High-quality cutting material and cutting edge

finish for very high service life requirements

Execution: Precise thread milling of profiles

Three-flute cutter in full profile design (indexable

inserts type A25 in four-flute cutter design)

p. 241 p. 254 p. 284

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13397580-630 100 80 60 80 60 120 180 100 160 80 140 140 60 30 30 30 60

Indexable insert Suitable for Pitch (mm) Suitable for Suitable for Number of teeth Cutting edge Ø fz steel 1300 13397...

type holder metric threads metric fine (PCS) (mm) (mm) Ident. No.

from threads from

A10 A1 | A2 | A12 0.5 - MF10 6 9 0.10 580 ●

| A13

A10 A1 | A2 | A12 1.0 - MF12 3 10 0.10 582 ●

| A13

A10 A1 | A2 | A12 1.5 - MF13 2 10 0.10 584 ●

| A13

A10 A1 | A2 | A12 1.75 M12 MF13 1 9.6 0.10 586 ●

| A13

A10 A1 | A2 | A12 2.0 M14 MF14 1 10 0.10 588 ●

A12 A3 | A4 | A5 0.5 - MF13 6 12 0.12 590 ●

| A14

A12 A3 | A4 | A5 0.75 - MF13 4 12 0.12 592 ●

| A14

A12 A3 | A4 | A5 1.0 - MF14 3 12 0.12 594 ●

| A14

A12 A3 | A4 | A5 1.5 - MF15 2 12 0.12 596 ●

| A14

A12 A3 | A4 | A5 2.0 M16 MF16 1 12.4 0.12 598 ●

| A14

A12 A3 | A4 | A5 2.5 M18 | M20 MF17 1 12 0.12 600 ●

A12 A3 | A4 | A5 3.0 - MF17 1 12.4 0.16 602 ●

A18 A6 | A7 | A8 | 0.5 - MF19 9 17.8 0.16 604 ●

A9 | A15

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 257

Availability subject to country specific rules and regulations.