Page 374 - Icon Ridge Industrial Tools Catalog

P. 374

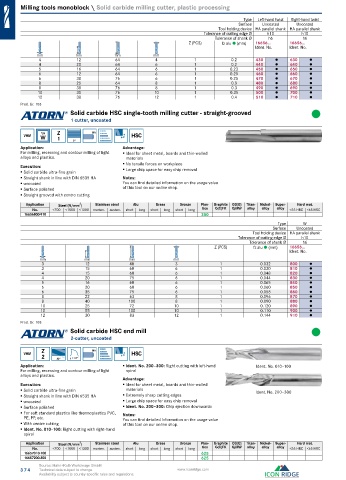

Milling tools monoblock \ Solid carbide milling cutter, plastic processing

Type Left-hand twist Right-hand twist

Surface Uncoated Uncoated

Tool holding device HA parallel shank HA parallel shank

Tolerance of cutting edge Ø h10 h10

Tolerance of shank Ø h6 h6

Z (PCS) fz alu (mm) 16656... 16656...

Ident. No. Ident. No.

mm mm mm mm

4 12 64 4 1 0.2 430 ● 630 ●

4 20 64 6 1 0.2 440 ● 640 ●

5 16 64 6 1 0.23 450 ● 650 ●

6 12 64 6 1 0.25 460 ● 660 ●

6 38 76 6 1 0.25 470 ● 670 ●

8 25 64 8 1 0.3 480 ● 680 ●

8 38 76 8 1 0.3 490 ● 690 ●

10 30 76 10 1 0.35 500 ● 700 ●

12 38 76 12 1 0.4 510 ● 710 ●

Prod. Gr. 108

Solid carbide HSC single-tooth milling cutter - straight-grooved

1 cutter, uncoated

Typ Z HA

VHM HSC

W 1 0°

Application: Advantage:

For milling, recessing and contour milling of light Ideal for sheet metal, boards and thin-walled

alloys and plastics. materials

Execution: No tensile forces on workpiece

Solid carbide ultra-fine grain Large chip space for easy chip removal

Straight shank in line with DIN 6535 HA Notes:

uncoated You can find detailed information on the usage value

Surface polished of this tool on our online shop.

Straight grooved with centre cutting

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16656800-910 350

Type W

Surface Uncoated

Tool holding device HA parallel shank

Tolerance of cutting edge Ø h10

Tolerance of shank Ø h6

Z (PCS) fz alu (mm) 16656...

Ident. No.

mm mm mm mm

3 12 40 3 1 0.032 800 ●

3 15 60 6 1 0.030 810 ●

4 15 60 6 1 0.048 820 ●

4 20 75 6 1 0.044 830 ●

5 16 60 6 1 0.065 840 ●

6 20 60 6 1 0.060 850 ●

6 35 75 6 1 0.058 860 ●

8 22 63 8 1 0.096 870 ●

8 40 100 8 1 0.090 880 ●

10 25 72 10 1 0.120 890 ●

10 55 100 10 1 0.110 900 ●

12 30 83 12 1 0.144 910 ●

Prod. Gr. 108

Solid carbide HSC end mill

2-cutter, uncoated

Z HA

VHM HSC

2 γ = 17°

Application: Ident. No. 200–300: Right cutting with left-hand Ident. No. 010–100

For milling, recessing and contour milling of light spiral

alloys and plastics.

Advantage:

Execution: Ideal for sheet metal, boards and thin-walled

Solid carbide ultra-fine grain materials Ident. No. 200–300

Straight shank in line with DIN 6535 HA Extremely sharp cutting edges

uncoated Large chip space for easy chip removal

Surface polished Ident. No. 200–300: Chip ejection downwards

For soft standard plastics like thermoplastics PVC, Notes:

PE, PP, etc. You can find detailed information on the usage value

With centre cutting of this tool on our online shop.

Ident. No. 010–100: Right cutting with right-hand

spiral

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16657010-100 625

16657200-300 625

Source: Hahn+Kolb Werkzeuge GmbH

374 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.