Page 421 - Icon Ridge Industrial Tools Catalog

P. 421

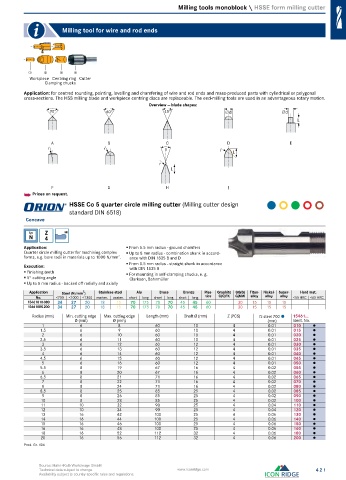

Milling tools monoblock \ HSSE form milling cutter

Milling tool for wire and rod ends

1 2 3 4

➀ Workpiece ➀ Centring ring ➀ Cutter ➀

Clamping chucks

Application: for centred rounding, pointing, levelling and chamfering of wire and rod ends and mass-produced parts with cylindrical or polygonal

cross-sections. The HSS milling blade and workpiece centring discs are replaceable. The end-milling tools are used in an advantageous rotary motion.

Overview — blade shapes:

90° 60° 45° d d

L

A B C D E

r r a r L

r

L

F G H J

h Prices on request.

HSSE Co 5 quarter circle milling cutter (Milling cutter design

standard DIN 6518)

Concave

Typ Z HB

N 4

Application: From 5.5 mm radius - ground chamfers

Quarter circle milling cutter for machining complex Up to 8 mm radius - combination shank in accord-

forms, e.g. bore radii in materials up to 1000 N/mm . 2 ance with DIN 1835 B and D

Execution: From 8.5 mm radius - straight shank in accordance

with DIN 1835 B

Finishing teeth For mounting in self-clamping chucks, e. g.

5° cutting angle Clarkson, Bahnmüller

Up to 5 mm radius - backed off radially and axially

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

15461010-080 34 27 20 18 15 70 175 70 70 45 45 60 30 15 15 15

15461085-200 34 27 20 18 15 70 175 70 70 45 45 60 30 15 15 15

Radius (mm) Min. cutting edge Max. cutting edge Length (mm) Shaft Ø (mm) Z (PCS) fz steel 700 15461...

Ø (mm) Ø (mm) (mm) Ident. No.

1 6 8 60 10 4 0.01 010 ●

1.5 6 9 60 10 4 0.01 015 ●

2 6 10 60 10 4 0.01 020 ●

2.5 6 11 60 10 4 0.01 025 ●

3 6 12 60 12 4 0.01 030 ●

3.5 6 13 60 12 4 0.01 035 ●

4 6 14 60 12 4 0.01 040 ●

4.5 6 15 60 12 4 0.01 045 ●

5 6 16 60 12 4 0.01 050 ●

5.5 8 19 67 16 4 0.02 055 ●

6 8 20 67 16 4 0.02 060 ●

6.5 8 21 71 16 4 0.02 065 ●

7 8 22 71 16 4 0.02 070 ●

8 8 24 71 16 4 0.02 080 ●

8.5 8 25 85 25 4 0.02 085 ●

9 8 26 85 25 4 0.02 090 ●

10 8 28 85 25 4 0.02 100 ●

11 10 32 90 25 4 0.04 110 ●

12 10 34 90 25 4 0.04 120 ●

13 16 42 100 25 4 0.06 130 ●

14 16 44 100 25 4 0.06 140 ●

15 16 46 100 25 4 0.06 150 ●

16 16 48 100 25 4 0.06 160 ●

18 16 52 112 32 4 0.06 180 ●

20 16 56 112 32 4 0.06 200 ●

Prod. Gr. 106

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 421

Availability subject to country specific rules and regulations.