Page 480 - Icon Ridge Industrial Tools Catalog

P. 480

Lathe tools \ Technical introduction–turning - ISO turning

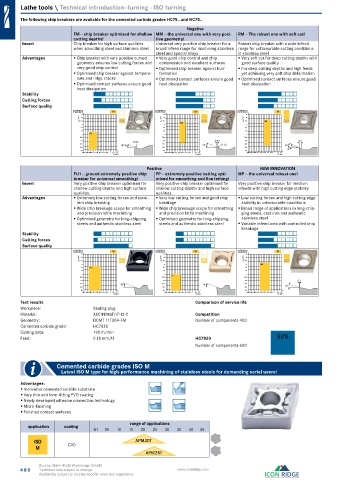

The following chip breakers are available for the cemented carbide grades HC75.. and HC78..

Negative

FM – chip breaker optimised for shallow MM – the universal one with very posi- RM – The robust one with soft cut!

cutting depths! tive geometry!

Insert Chip breaker for high surface qualities Universal very positive chip breaker for a Robust chip breaker with a wide infeed

when smoothing steel and stainless steel broad infeed range for machining stainless range for unfavourable cutting conditions

steel and special alloys in stainless steel

Advantages Chip breaker with very positive curved Very good chip control and chip Very soft cut for deep cutting depths with

geometry ensures low cutting forces and compression and excellent surfaces good surface quality

very good chip control Optimised chip breaker against burr For deep cutting depths and high feeds

Optimised chip breaker against tempera- formation yet achieving very soft chip deformation

ture and ridge cracks Optimised contact surfaces ensure good Optimised contact surfaces ensure good

Optimised contact surfaces ensure good heat dissipation heat dissipation

heat dissipation

Stability

Cutting forces

Surface quality

M M M

16 16 16

a ( mm ) p 10 FM a ( mm ) p 10 MM a ( mm ) p 10 RM

6,3

6,3

MM 6,3 RM

4 4 4

2,5 2,5 2,5

1,6 1,6 1,6

FM

1 1 1

0,63 0,63 0,63

0,4 R 0,5 0,4 0,04 0,4 0,3

0,25 18°30' 0,25 20° R 1,2 0,25 20°

0,16 0,16 0,16 10°

0,1 0,1 0,1

0,025 0,04 0,063 0,1 0,16 0,25 0,4 0,63 1 1,6 2,5 0,025 0,04 0,063 0,1 0,16 0,25 0,4 0,63 1 1,6 2,5 0,025 0,04 0,063 0,1 0,16 0,25 0,4 0,63 1 1,6 2,5

f ( mm ) f ( mm ) f ( mm )

Positive NEW INNOVATION

FU1 – ground extremely positive chip FP – extremely positive cutting opti- MP – the universal robust one!

breaker for universal smoothing! mised for smoothing and fine lathing!

Insert Very positive chip breaker optimised for Very positive chip breaker optimised for Very positive chip breaker for medium

shallow cutting depths and high surface shallow cutting depths and high surface infeeds with high cutting edge stability

qualities. qualities.

Advantages Extremely low cutting forces and excel- Very low cutting forces and good chip Low cutting forces and high cutting edge

lent chip breaking breakage stability in unfavourable conditions

Wide chip breakage scope for smoothing Wide chip breakage scope for smoothing Broad range of applications in long-chip-

and precision lathe machining and precision lathe machining ping steels, cast iron and authentic

Optimised geometry for long-chipping Optimised geometry for long-chipping stainless steel

steels and authentic stainless steel steels and authentic stainless steel Variable infeed area with controlled chip

breakage

Stability

Cutting forces

Surface quality

M M M

16 16 16

a ( mm ) p 10 6,3 FU1 a ( mm ) p 10 6,3 FP a ( mm ) p 10 6,3 MP

4 4 4 MP

2,5 FU1 2,5 2,5

1,6 1,6 1,6

1 1 1

FP

0,63 0,63 0,63

0,4 0,4 0,4 0,1

0,25 18° 0,25 18° 0,25

0,16 0,16 0,16 12°

0,1 0,1 0,1

0,025 0,04 0,063 0,1 0,16 0,25 0,4 0,63 1 1,6 2,5 0,025 0,04 0,063 0,1 0,16 0,25 0,4 0,63 1 1,6 2,5 0,025 0,04 0,063 0,1 0,16 0,25 0,4 0,63 1 1,6 2,5

f ( mm ) f ( mm ) f ( mm )

Test results Comparison of service life

Workpiece: Sealing plug

Material: X6CrNiMoTi17-12-2 Competition

Geometry: DCMT 11T304-FM Number of components 400

Cemented carbide grade: HC7820

Cutting data: 190 m/min

Feed: 0.18 mm/U HC7820 50%

Number of components 600

Cemented carbide grades ISO M

Latest ISO M type for high-performance machining of stainless steels for demanding serial users!

Advantages:

Innovative cemented carbide substrate

Very thin and form-fitting PVD coating

Newly developed adhesive connection technology

Micro-finishing

Polished contact surfaces

range of applications

application coating

01 05 10 15 20 25 30 35 40 45

ISO CVD APM20T

M

APM25T

Source: Hahn+Kolb Werkzeuge GmbH

480 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.