Page 675 - Icon Ridge Industrial Tools Catalog

P. 675

Lathe tools \ Technical introduction - knurling

Technical information, knurl pressing

in knurl pressing, the material is subject to chipless deformation. The material is cold-formed via the knurling wheel and flows outwards. This forming process

increases the diameter of the workpiece. The following list provides an overview of bulging for the various pitches and materials.

the most suitable knurling materials are:

All ferrous materials with a stability of max. 1700 N/mm2 and an elongation of at least 4 - 5%

Non-ferrous base metals

Hardwood

Plastic corresponding to the requirements of the elongation and tensile strength

An increase in diameter is a particular characteristic of knurl forming. A diameter increase of approx. 40% of the used knurling pitch is considered an empirical value

for larger initial diameters. the initial diameter can be calculated according to the following formula:

d2 = Starting diameter (rotation diameter) [mm]

d1 = End diameter [mm]

d 2 = d 1 – (X · t) X = The value X can be derived from the following table

t = Pitch

Knurl form Value X

Parallel to axis, form AA 0.50

Left knurl, form BL 0.50

Right knurl, form BR 0.50

Cross knurl, tips raised, form KE 0.67

Cross knurl, tips recessed, form KV 0.33

Left/right knurl, tips raised, form GE 0.67

Left/right knurl, tips recessed, form GV 0.33

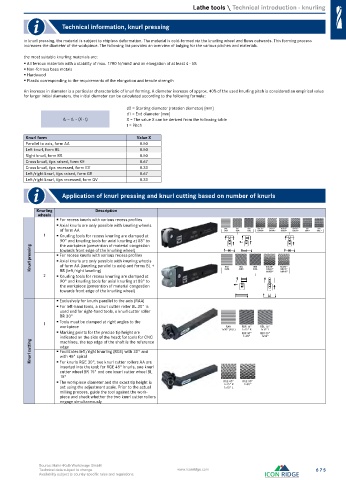

Application of knurl pressing and knurl cutting based on number of knurls

Knurling Description

wheels

For recess knurls with various recess profiles

Axial knurls are only possible with knurling wheels

of form AA 1xAA RBL 1xBL RGE30° 1xGV45° 1xGE30° RGV45° 1xKV * 1xKE *

RBR

RAA

RKE

RGV30°

RKV

RGE45°

1xBR

1xGV30°

1xGE45°

1 Knurling tools for recess knurling are clamped at

90° and knurling tools for axial knurling at 88° to

the workpiece (prevention of material congestion

Knurl pressing For recess knurls with various recess profiles

towards front edge of the knurling wheel)

Axial knurls are only possible with knurling wheels

of form AA (knurling parallel to axis) and forms BL +

RGE30°

RBL

RGE45°

BR (left/right knurling)

2xAA

2xBL

1xBR45°

1xBR30°

2 Knurling tools for recess knurling are clamped at RAA 2xBR RBR 1xBL30° 1xBL45°

90° and knurling tools for axial knurling at 88° to

the workpiece (prevention of material congestion

towards front edge of the knurling wheel)

Exclusively for knurls parallel to the axis (RAA)

For left-hand tools, a knurl cutter roller BL 30° is

used and for right-hand tools, a knurl cutter roller

BR 30°

1 Tools must be clamped at right angles to the

workpiece RAA RBR 15° RBL 15°

1x15° L

Marking points for the precise tip height are 1x30° (R/L) 1x15° R RBR 30°

RBR 30°

indicated on the side of the head; for tools for CNC 1x90° 1x90°

machines, the top edge of the shaft is the reference

Knurl cutting Facilitates left/right knurling (RGE) with 30° and

edge

with 45° spiral

For knurls RGE 30°, two knurl cutter rollers AA are

inserted into the tool; for RGE 45° knurls, one knurl

cutter wheel BR 15° and one knurl cutter wheel BL

2 15°

The workpiece diameter and the exact tip height is RGE 45° RGE 30°

2x90°

1x15° R

set using the adjustment scale. Prior to the actual 1x15° L

milling process, guide the tool against the work-

piece and check whether the two knurl cutter rollers

engage simultaneously

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 675

Availability subject to country specific rules and regulations.