Page 677 - Icon Ridge Industrial Tools Catalog

P. 677

Lathe tools \ Technical introduction - knurling

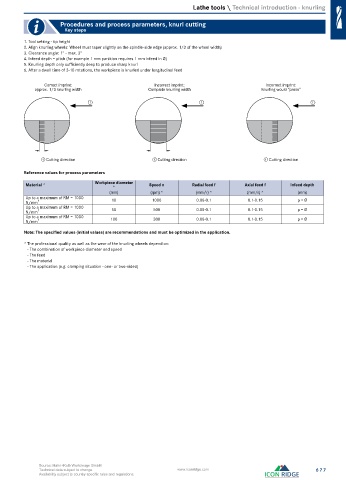

Procedures and process parameters, knurl cutting

Key steps

1. Tool setting - tip height

2. Align knurling wheels: Wheel must taper slightly on the spindle-side edge (approx. 1/3 of the wheel width)

3. Clearance angle: 1° - max. 3°

4. Infeed depth = pitch (for example 1 mm partition requires 1 mm infeed in Ø)

5. Knurling depth only sufficiently deep to produce sharp knurl

6. After a dwell time of 3-10 rotations, the workpiece is knurled under longitudinal feed

Correct imprint: Incorrect imprint: Incorrect imprint:

approx. 1/3 knurling width Complete knurling width Knurling would “press”

1 1 1

① Cutting direction ① Cutting direction ① Cutting direction

Reference values for process parameters

Material * Workpiece diameter Speed n Radial feed f Axial feed f Infeed depth

*

(mm) (rpm) * (mm/r) * (mm/r) * (mm)

Up to a maximum of RM = 1000 10 1000 0.08-0.1 0.1-0.15 p = Ø

N/mm 2

Up to a maximum of RM = 1000 50 500 0.08-0.1 0.1-0.15 p = Ø

N/mm 2

Up to a maximum of RM = 1000 100 300 0.08-0.1 0.1-0.15 p = Ø

N/mm 2

Note: The specified values (initial values) are recommendations and must be optimized in the application.

* The professional quality as well as the wear of the knurling wheels depend on:

- The combination of workpiece diameter and speed

- The feed

- The material

- The application (e.g. clamping situation - one- or two-sided)

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 677

Availability subject to country specific rules and regulations.