Page 696 - Icon Ridge Industrial Tools Catalog

P. 696

Tool clamping \ Technical introduction – tool chucks

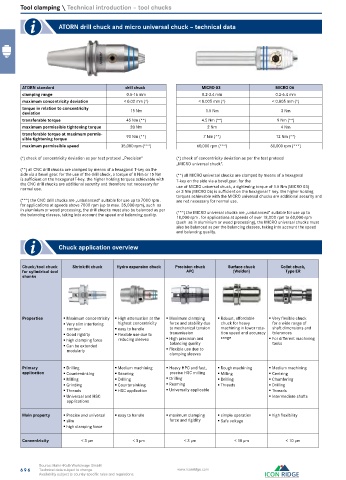

ATORN drill chuck and micro universal chuck – technical data

ATORN standard drill chuck MICRO 03 MICRO 06

clamping range 0.5-16 mm 0.2-3.4 mm 0.2-6.4 mm

maximum concentricity deviation < 0.02 mm (*) < 0.005 mm (*) < 0.005 mm (*)

torque in relation to concentricity

deviation 15 Nm 1.5 Nm 3 Nm

transferable torque 45 Nm (**) 4.5 Nm (**) 9 Nm (**)

maximum permissible tightening torque 20 Nm 2 Nm 4 Nm

transferable torque at maximum permis- 90 Nm (**) 7 Nm (**) 12 Nm (**)

sible tightening torque

maximum permissible speed 35,000 rpm (***) 60,000 rpm (***) 60,000 rpm (***)

(*) check of concentricity deviation as per test protocol „Precision“ (*) check of concentricity deviation as per the test protocol

„MICRO universal chuck“.

(**) all CNC drill chucks are clamped by means of a hexagonal T-key on the

side via a bevel gear. for the use of the drill chuck, a torque of 8 Nm or 15 Nm (**) all MICRO universal chucks are clamped by means of a hexagonal

is sufficient on the hexagonal T-key. the higher holding torques achievable with T-key on the side via a bevel gear. for the

the CNC drill chucks are additional security and therefore not necessary for use of MICRO universal chuck, a tightening torque of 1.5 Nm (MICRO 03)

normal use. or 3 Nm (MICRO 06) is sufficient on the hexagonal T-key. the higher holding

torques achievable with the MICRO universal chucks are additional security and

(***) the CNC drill chucks are „unbalanced“ suitable for use up to 7000 rpm . are not necessary for normal use.

for applications at speeds above 7000 rpm (up to max. 35,000 rpm), such as

in aluminium or wood processing, the drill chucks must also be balanced as per (***) the MICRO universal chucks are „unbalanced“ suitable for use up to

the balancing classes, taking into account the speed and balancing quality.

18,000 rpm . for applications at speeds of over 18,000 rpm to 60,000 rpm

(such as in aluminium or wood processing), the MICRO universal chucks must

also be balanced as per the balancing classes, taking into account the speed

and balancing quality.

Chuck application overview

Chuck/tool chuck Shrink-fit chuck Hydro expansion chuck Precision chuck Surface chuck Collet chuck,

for cylindrical tool APC (Weldon) Type ER

shanks

Properties Maximum concentricity High attenuation at the Maximum clamping Robust, affordable Very flexible chuck

Very slim interfering highest concentricity force and stability due chuck for heavy for a wide range of

contour easy to handle to mechanical tension machining in lower rota- shaft dimensions and

Good rigidity Flexible use due to transmission tion speed and accuracy tolerances

high clamping force reducing sleeves High precision and range For different machining

balancing quality

tasks

Can be extended

modularly Flexible use due to

clamping sleeves

Primary Drilling Medium machining Heavy HPC and fast, Rough machining Medium machining

application Countersinking Reaming precise HSC milling Milling Centring

Milling Drilling Drilling Drilling Chamfering

Grinding Countersinking Reaming Threads Drilling

Threads HSC application Universally applicable Threads

Universal and HSC Intermediate shafts

applications

Main property Precise and universal easy to handle maximum clamping simple operation high flexibility

slim force and rigidity Safe voltage

high clamping force

Concentricity < 3 μm < 3 μm < 3 μm < 10 μm < 10 μm

Source: Hahn+Kolb Werkzeuge GmbH

696 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.