Page 701 - Icon Ridge Industrial Tools Catalog

P. 701

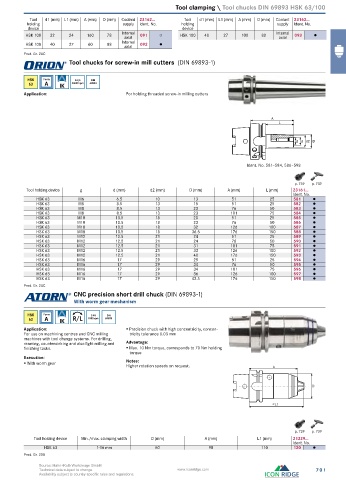

Tool clamping \ Tool chucks DIN 69893 HSK 63/100

Tool d1 (mm) L1 (mm) A (mm) D (mm) Coolant 23162... Tool d1 (mm) L1 (mm) A (mm) D (mm) Coolant 23162...

holding supply Ident. No. holding supply Ident. No.

device device

HSK 100 32 24 160 78 Internal 091 ○ HSK 100 40 27 100 88 Internal 093 ●

axial

axial

HSK 100 40 27 60 88 Internal 092 ●

axial

Prod. Gr. 2AC

Tool chucks for screw-in mill cutters (DIN 69893-1)

HSK Form G 2,5 DIN

63 A IK 20000 rpm 69893

Application: For holding threaded screw-in milling cutters

A

L

g d d2 D

Ident. No. 581–584, 586–598

p. 739 p. 739

Tool holding device g d (mm) d2 (mm) D (mm) A (mm) L (mm) 23161...

Ident. No.

HSK 63 M6 6.5 10 13 51 25 581 ●

HSK 63 M8 8.5 13 15 51 25 582 ●

HSK 63 M8 8.5 13 23 76 50 583 ●

HSK 63 M8 8.5 13 23 101 75 584 ●

HSK 63 M10 10.5 18 20 51 25 585 ●

HSK 63 M10 10.5 18 23 76 50 586 ●

HSK 63 M10 10.5 18 32 126 100 587 ●

HSK 63 M10 10.5 18 36.5 176 150 588 ●

HSK 63 M12 12.5 21 24 51 25 589 ●

HSK 63 M12 12.5 21 24 76 50 590 ●

HSK 63 M12 12.5 21 31 101 75 591 ●

HSK 63 M12 12.5 21 33 126 100 592 ●

HSK 63 M12 12.5 21 40 176 150 593 ●

HSK 63 M16 17 29 29 51 25 594 ●

HSK 63 M16 17 29 34 76 50 595 ●

HSK 63 M16 17 29 34 101 75 596 ●

HSK 63 M16 17 29 36 126 100 597 ●

HSK 63 M16 17 29 42.5 176 150 598 ●

Prod. Gr. 2AC

CNC precision short drill chuck (DIN 69893-1)

With worm gear mechanism

HSK Form G 40 DIN

63 A IK R/ L 7000 rpm 69893

Application: Precision chuck with high concentricity, concen-

For use on machining centres and CNC milling tricity tolerance 0.03 mm

machines with tool change systems. For drilling,

reaming, countersinking and also light milling and Advantage:

finishing tasks. Max. 10 Nm torque, corresponds to 70 Nm holding

torque

Execution:

With worm gear Notes:

Higher rotation speeds on request. A

D

~ ~ L1

p. 739 p. 739

Tool holding device Min./max. clamping width D (mm) A (mm) L1 (mm) 21329...

Ident. No.

HSK 63 1-16 mm 50 98 110 120 ●

Prod. Gr. 208

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 701

Availability subject to country specific rules and regulations.