Page 704 - Icon Ridge Industrial Tools Catalog

P. 704

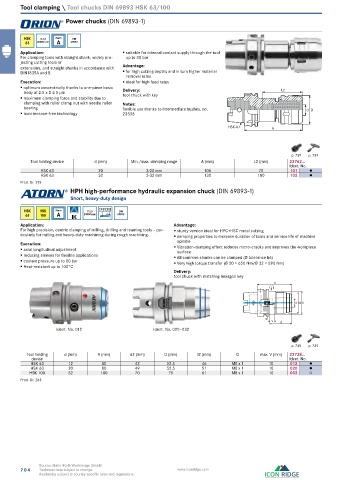

Tool clamping \ Tool chucks DIN 69893 HSK 63/100

Power chucks (DIN 69893-1)

HSK G 6,3 Form DIN

63 20000 rpm A 69893

Application: suitable for internal coolant supply through the tool

For clamping tools with straight shank, widely pro- up to 80 bar

jecting cutting tools or

extensions, and straight shanks in accordance with Advantage:

DIN1835A and B. for high cutting depths and in turn higher material

removal rates

Execution: ideal for high feed rates

optimum concentricity thanks to one-piece basic Delivery: L2

body at 2.5 x D ≤ 5 µm tool chuck with key

maximum clamping force and stability due to

clamping with roller clamp nut with needle roller Notes:

bearing flexible use thanks to intermediate bushes, no. d D

maintenance-free technology 23336

HSK-A A

p. 739 p. 739

Tool holding device d (mm) Min./max. clamping range A (mm) L2 (mm) 23762...

Ident. No.

HSK 63 20 3-20 mm 105 70 101 ●

HSK 63 32 3-32 mm 130 100 102 ●

Prod. Gr. 295

HPH high-performance hydraulic expansion chuck (DIN 69893-1)

Short, heavy-duty design

HSK HSK Form G 2,5 < – 0,003 DIN

63 100 A IK 25000 rpm 69893

Application: Advantage:

For high precision, centric clamping of milling, drilling and reaming tools – par- sturdy version ideal for HPC+HSC metal cutting

ticularly for milling and heavy-duty machining during rough machining. damping properties to increase duration of tools and service life of machine

Execution: spindle

axial longitudinal adjustment Vibration-damping effect reduces micro-cracks and improves the workpiece

surface

reducing sleeves for flexible applications All common shanks can be clamped (Ø tolerance h6)

coolant pressure up to 80 bar Very high torque transfer (Ø 20 = 650 Nm/Ø 32 = 890 Nm)

Heat-resistant up to 100°C

Delivery:

tool chuck with matching hexagon key

A

d d2 D

G

V l2

Ident. No. 012 Ident. No. 020–032

p. 739 p. 739

Tool holding d (mm) A (mm) d2 (mm) D (mm) l2 (mm) G max. V (mm) 23738...

device Ident. No.

HSK 63 12 80 42 52.5 46 M8 x 1 10 012 ●

HSK 63 20 80 49 52.5 51 M8 x 1 10 020 ●

HSK 100 32 100 70 75 61 M8 x 1 10 032 ○

Prod. Gr. 263

Source: Hahn+Kolb Werkzeuge GmbH

704 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.