Page 705 - Icon Ridge Industrial Tools Catalog

P. 705

Tool clamping \ Tool chucks DIN 69893 HSK 63/100

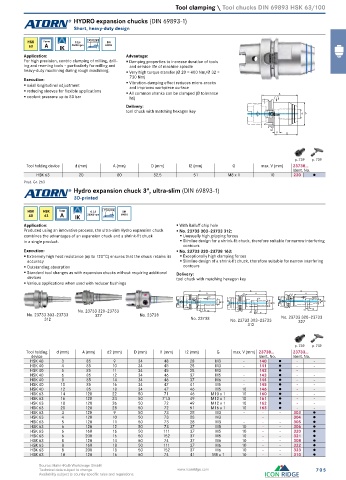

HYDRO expansion chucks (DIN 69893-1)

Short, heavy-duty design

HSK Form G 2,5 < – 0,003 DIN

63 A IK 25000 rpm 69893

Application: Advantage:

For high precision, centric clamping of milling, drill- Damping properties to increase duration of tools

ing and reaming tools – particularly for milling and and service life of machine spindle

heavy-duty machining during rough machining. Very high torque transfer (Ø 20 = 400 Nm/Ø 32 =

730 Nm)

Execution: Vibration-damping effect reduces micro-cracks

axial longitudinal adjustment and improves workpiece surface

reducing sleeves for flexible applications All common shanks can be clamped (Ø tolerance

coolant pressure up to 80 bar h6) A

Delivery:

tool chuck with matching hexagon key

d D

G

V l2

p. 739 p. 739

Tool holding device d (mm) A (mm) D (mm) l2 (mm) G max. V (mm) 23738...

Ident. No.

HSK 63 20 80 52.5 51 M8 x 1 10 220 ●

Prod. Gr. 263

Hydro expansion chuck 3°, ultra-slim (DIN 69893-1)

3D-printed

HSK HSK Form G 2,5 < – 0,003 DIN

40 63 A IK 25000 rpm 69893

Application: With Balluff chip hole

Produced using an innovative process, the ultra-slim Hydro expansion chuck No. 23733 303–23733 312:

combines the advantages of an expansion chuck and a shrink-fit chuck Unusually high gripping forces

in a single product. Slimline design for a shrink-fit chuck, therefore suitable for narrow interfering

contours

Execution: No. 23733 320–23738 163:

Extremely high heat resistance (up to 120°C) ensures that the chuck retains its Exceptionally high clamping forces

accuracy Slimline design of a shrink-fit chuck, therefore suitable for narrow interfering

Outstanding absorption contours

Standard tool changes as with expansion chucks without requiring additional Delivery:

devices tool chuck with matching hexagon key

Various applications when used with reducer bushings

A A A

l1 l1 l1

3° 3° 5,8°

3°

d d2 D

d d2 D d d2 D

No. 23733 320–23733 G V l2 V G V l2

No. 23733 303–23733 327 No. 23738 G l2

312 No. 23738 No. 23733 303–23733 No. 23733 320–23733

327

312

p. 739 p. 739

Tool holding d (mm) A (mm) d2 (mm) D (mm) l1 (mm) l2 (mm) G max. V (mm) 23738... 23733...

device Ident. No. Ident. No.

HSK 40 3 85 9 34 48 28 M3 - 140 ● - -

HSK 40 4 85 10 34 45 28 M3 - 141 ● - -

HSK 40 5 85 11 34 45 28 M3 - 142 ● - -

HSK 40 6 85 12 34 46 37 M5 - 143 ● - -

HSK 40 8 85 14 34 46 37 M6 - 144 ● - -

HSK 40 10 85 16 34 47 41 M5 - 145 ● - -

HSK 40 12 85 18 34 47 46 M5 10 146 ● - -

HSK 63 14 120 22 50 71 46 M10 x 1 10 160 ● - -

HSK 63 16 120 24 50 71.5 49 M12 x 1 10 161 ● - -

HSK 63 18 120 26 50 72 49 M12 x 1 10 162 ● - -

HSK 63 20 120 28 50 72 51 M16 x 1 10 163 ● - -

HSK 63 3 120 9 50 73 28 M3 - - - 303 ●

HSK 63 4 120 10 50 73 28 M3 - - - 304 ●

HSK 63 5 120 11 50 73 28 M3 - - - 305 ●

HSK 63 6 120 12 50 73 37 M5 10 - - 306 ●

HSK 63 6 160 16 50 111 37 M5 10 - - 320 ●

HSK 63 6 200 16 50 152 37 M5 10 - - 321 ●

HSK 63 8 120 14 50 74 37 M6 10 - - 308 ●

HSK 63 8 160 18 50 111 37 M6 10 - - 322 ●

HSK 63 8 200 18 50 152 37 M6 10 - - 323 ●

HSK 63 10 120 16 50 74 41 M8 x 1 10 - - 310 ●

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 705

Availability subject to country specific rules and regulations.