Page 717 - Icon Ridge Industrial Tools Catalog

P. 717

Tool clamping \ Tool chucks ISO 7388-1 SK 40/50

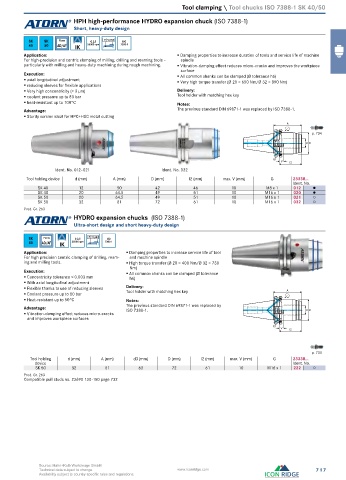

HPH high-performance HYDRO expansion chuck (ISO 7388-1)

Short, heavy-duty design

SK SK Form G 2,5 < – 0,003 ISO

40 50 AD/AF IK 25000 rpm 7388-1

Application: Damping properties to increase duration of tools and service life of machine

For high-precision and centric clamping of milling, drilling and reaming tools – spindle

particularly with milling and heavy-duty machining during rough machining. Vibration-damping effect reduces micro-cracks and improves the workpiece

surface

Execution: All common shanks can be clamped (Ø tolerance h6)

axial longitudinal adjustment Very high torque transfer (Ø 20 = 650 Nm/Ø 32 = 890 Nm)

reducing sleeves for flexible applications

Very high concentricity (< 3 µm) Delivery:

coolant pressure up to 80 bar Tool holder with matching hex key

heat-resistant up to 100°C Notes:

Advantage: The previous standard DIN 69871-1 was replaced by ISO 7388-1.

Sturdy version ideal for HPC+HSC metal cutting

A

p. 734

d D

G

V l2

Ident. No. 012–021 Ident. No. 032

Tool holding device d (mm) A (mm) D (mm) l2 (mm) max. V (mm) G 23338...

Ident. No.

SK 40 12 50 42 46 10 M8 x 1 012 ●

SK 40 20 64.5 49 51 10 M16 x 1 020 ●

SK 50 20 64.5 49 51 10 M16 x 1 021 ○

SK 50 32 81 72 61 10 M16 x 1 032 ○

Prod. Gr. 263

HYDRO expansion chucks (ISO 7388-1)

Ultra-short design and short heavy-duty design

SK Form G 2,5 < – 0,003 ISO

50 AD/AF IK 25000 rpm 7388-1

Application: Damping properties to increase service life of tool

For high precision centric clamping of drilling, ream- and machine spindle

ing and milling tools. High torque transfer (Ø 20 = 400 Nm/Ø 32 = 730

Nm)

Execution: All common shanks can be clamped (Ø tolerance

Concentricity tolerance < 0.003 mm h6)

With axial longitudinal adjustment

Flexible thanks to use of reducing sleeves Delivery: A

Coolant pressure up to 80 bar Tool holder with matching hex key

Heat-resistant up to 50°C Notes:

Advantage: The previous standard DIN 69871-1 was replaced by d D

ISO 7388-1.

Vibration-damping effect reduces micro-cracks

and improves workpiece surfaces

G

V l2

p. 734

Tool holding d (mm) A (mm) d3 (mm) D (mm) l2 (mm) max. V (mm) G 23338...

device Ident. No.

SK 50 32 81 63 72 61 10 M16 x 1 222 ○

Prod. Gr. 263

Compatible pull studs no. 23690 130-150 page 732

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 717

Availability subject to country specific rules and regulations.