Page 715 - Icon Ridge Industrial Tools Catalog

P. 715

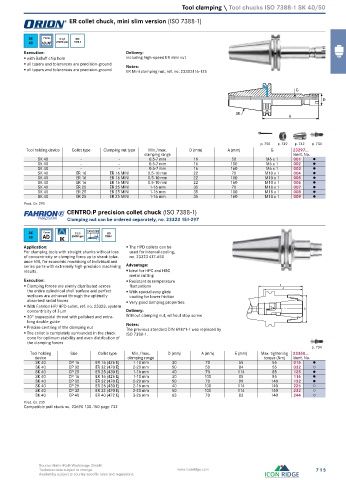

Tool clamping \ Tool chucks ISO 7388-1 SK 40/50

ER collet chuck, mini slim version (ISO 7388-1)

SK Form G 2,5 ISO

40 AD/AF 25000 rpm 7388-1

Execution: Delivery:

with Balluff chip hole including high-speed ER mini nut

all tapers and tolerances are precision-ground Notes:

all tapers and tolerances are precision-ground ER Mini clamping nut, ref. no. 23303116-125

G

D

SK

A

p. 750 p. 749 p. 742 p. 734

Tool holding device Collet type Clamping nut type Min./max. D (mm) A (mm) G 23297...

clamping range Ident. No.

SK 40 - - 0.5-7 mm 16 50 M6 x 1 001 ●

SK 40 - - 0.5-7 mm 16 100 M6 x 1 002 ●

SK 40 - - 0.5-7 mm 16 160 M6 x 1 003 ●

SK 40 ER 16 ER 16 MINI 0.5-10 mm 22 70 M10 x 1 004 ●

SK 40 ER 16 ER 16 MINI 0.5-10 mm 22 100 M10 x 1 005 ●

SK 40 ER 16 ER 16 MINI 0.5-10 mm 22 160 M10 x 1 006 ●

SK 40 ER 25 ER 25 MINI 1-16 mm 35 70 M18 x 1 007 ●

SK 40 ER 25 ER 25 MINI 1-16 mm 35 100 M18 x 1 008 ●

SK 40 ER 25 ER 25 MINI 1-16 mm 35 160 M18 x 1 009 ●

Prod. Gr. 295

CENTRO|P precision collet chuck (ISO 7388-1)

Clamping nut can be ordered separately, no. 23323 151-297

SK Form G 2,5 < – 0,003 ISO

40 AD IK 25000 rpm 7388-1

Application: The HPD collets can be

For clamping tools with straight shanks without loss used for internal cooling,

of concentricity or clamping force up to shank toler- no. 23323 617-658

ance h10, for economic machining of individual and

series parts with extremely high-precision machining Advantage:

results. Ideal for HPC and HSC

metal cutting

Execution: Resistant to temperature

Clamping forces are evenly distributed across fluctuations E A

the entire cylindrical shell surface and perfect With special easy glide

surfaces are achieved through the optimally coating for lower friction

absorbed radial forces Very good damping properties

With Fahrion HP/HPD collet, ref. no. 23323, system

concentricity of 3 µm Delivery: D

30° trapezoidal thread with polished and extra- Without clamping nut, without stop screw

long double guide

Precise centring of the clamping nut Notes:

The previous standard DIN 69871-1 was replaced by

The collet is completely surrounded in the chuck ISO 7388-1.

cone for optimum stability and even distribution of

the clamping forces

p. 734

Tool holding Size Collet type Min./max. D (mm) A (mm) E (mm) Max. tightening 23360...

device clamping range torque (Nm) Ident. No.

SK 40 CP 16 ER 16 (426 E) 1-10 mm 30 70 55 55 016 ●

SK 40 CP 32 ER 32 (470 E) 2-20 mm 50 50 84 55 032 ○

SK 40 CP 25 ER 25 (430 E) 1-16 mm 40 70 114 85 125 ●

SK 40 CP 16 ER 16 (426 E) 1-10 mm 30 100 85 85 116 ●

SK 40 CP 32 ER 32 (470 E) 2-20 mm 50 70 99 140 132 ●

SK 40 CP 25 ER 25 (430 E) 2-16 mm 40 100 114 140 225 ○

SK 40 CP 32 ER 32 (470 E) 2-20 mm 50 100 114 140 232 ○

SK 40 CP 40 ER 40 (472 E) 3-26 mm 63 70 83 140 244 ○

Prod. Gr. 235

Compatible pull studs no. 23690 130-150 page 732

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 715

Availability subject to country specific rules and regulations.