Page 215 - Industrial Tools Catalog (1)

P. 215

Thread tools \ Hand tap M

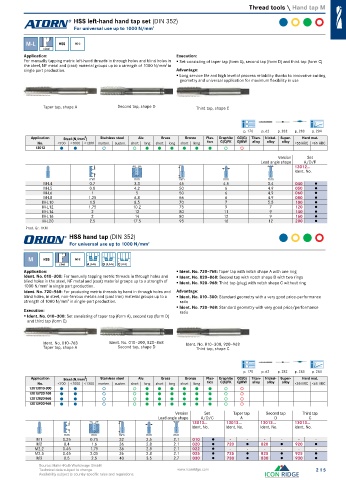

HSS left-hand hand tap set (DIN 352)

For universal use up to 1000 N/mm 2

M-L HSS

3xd

Application: Execution:

For manually tapping metric left-hand threads in through holes and blind holes in Set consisting of taper tap (form A), second tap (form D) and third tap (form C)

the steel, NF metal and (cast) material groups up to a strength of 1000 N/mm in

2

single part production. Advantage:

Long service life and high level of process reliability thanks to innovative cutting

geometry and universal application for maximum flexibility in use

Taper tap, shape A Second tap, shape D Third tap, shape C

p. 170 p. 62 p. 282 p. 283 p. 284

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13012

Version Set

Lead angle shape A/D/F

13012...

Ident. No.

mm mm mm mm mm

M-L4 0.7 3.3 45 4.5 3.4 040 ●

M-L5 0.8 4.2 50 6 4.9 050 ●

M-L6 1 5 50 6 4.9 060 ●

M-L8 1.25 6.8 56 6 4.9 080 ●

M-L10 1.5 8.5 70 7 5.5 100 ●

M-L12 1.75 10.2 75 9 7 120 ●

M-L14 2 12 80 11 9 140 ●

M-L16 2 14 80 12 9 160 ●

M-L20 2.5 17.5 95 16 12 200 ●

Prod. Gr. 1KM

HSS hand tap (DIN 352)

For universal use up to 1000 N/mm 2

M HSS

3xd A (6-8) D (3,5-5) C (2-3)

Application: Ident. No. 720–768: Taper tap with notch shape A with one ring

Ident. No. 010–300: For manually tapping metric threads in through holes and Ident. No. 820–868: Second tap with notch shape D with two rings

blind holes in the steel, NF metal and (cast) material groups up to a strength of Ident. No. 920–968: Third tap (plug) with notch shape C without ring

1000 N/mm in single part production.

2

Ident. No. 720–968: For producing metric threads by hand in through holes and Advantage:

blind holes, in steel, non-ferrous metals and (cast iron) material groups up to a Ident. No. 010–300: Standard geometry with a very good price-performance

strength of 1000 N/mm in single-part production. ratio

2

Ident. No. 720–968: Standard geometry with very good price/performance

Execution: ratio

Ident. No. 010–300: Set consisting of taper tap (form A), second tap (form D)

and third tap (form C)

Ident. No. 010–768 Ident. No. 010–300, 820–868 Ident. No. 010–300, 920–968

Taper tap, shape A Second tap, shape D Third tap, shape C

p. 170 p. 62 p. 282 p. 283 p. 284

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13013010-300

13013720-768

13013820-868

13013920-968

Version Set Taper tap Second tap Third tap

Lead angle shape A/D/C A D C

13013... 13013... 13013... 13013...

Ident. No. Ident. No. Ident. No. Ident. No.

mm mm mm mm mm

M1 0.25 0.75 32 2.5 2.1 010 ● - - - - - -

M2 0.4 1.6 36 2.8 2.1 020 ● 720 ● 820 ● 920 ●

M2.2 0.45 1.75 36 2.8 2.1 022 ● - - - - - -

M2.5 0.45 2.05 36 2.8 2.1 025 ● 725 ● 825 ● 925 ●

M3 0.5 2.5 40 3.5 2.7 030 ● 730 ● 830 ● 930 ●

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 215

Availability subject to country specific rules and regulations.