Page 218 - Industrial Tools Catalog (1)

P. 218

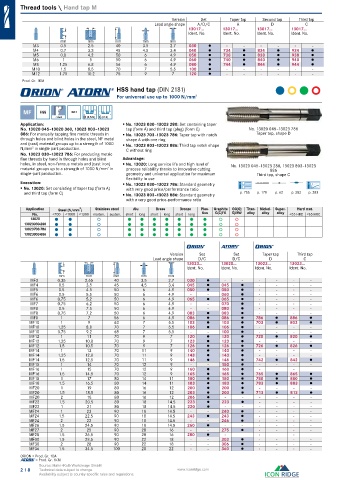

Thread tools \ Hand tap M

Version Set Taper tap Second tap Third tap

Lead angle shape A/D/C A D C

13017... 13017... 13017... 13017...

Ident. No. Ident. No. Ident. No. Ident. No.

mm mm mm mm mm

M3 0.5 2.5 40 3.5 2.7 030 ● - - - - - -

M4 0.7 3.3 45 4.5 3.4 040 ● 734 ● 834 ● 934 ●

M5 0.8 4.2 50 6 4.9 050 ● 738 ● 838 ● 938 ●

M6 1 5 50 6 4.9 060 ● 740 ● 840 ● 940 ●

M8 1.25 6.8 56 6 4.9 080 ● 744 ● 844 ● 944 ●

M10 1.5 8.5 70 7 5.5 100 ● - - - - - -

M12 1.75 10.2 75 9 7 120 ● - - - - - -

Prod. Gr. 1KM

HSS hand tap (DIN 2181)

For universal use up to 1000 N/mm 2

MF HSS

3xd D (3,5-5) C (2-3)

Application: No. 13023 030–13023 280: Set containing taper

No. 13020 045–13020 360, 13023 803–13023 tap (form A) and third tap (plug) (form C) No. 13020 045–13023 786

886: For manually tapping fine metric threads in No. 13023 703–13023 786: Taper tap with notch Taper tap, shape D

through holes and blind holes in the steel, NF metal shape A with one ring

and (cast) material groups up to a strength of 1000 No. 13023 803–13023 886: Third tap notch shape

N/mm in single part production. C without ring

2

No. 13023 030–13023 786: For producing metric

fine threads by hand in through holes and blind Advantage:

holes, in steel, non-ferrous metals and (cast iron) No. 13020: Long service life and high level of No. 13020 045–13023 280, 13023 803–13023

material groups up to a strength of 1000 N/mm in process reliability thanks to innovative cutting 886

2

single-part production. geometry and universal application for maximum Third tap, shape C

flexibility in use

Execution: No. 13023 030–13023 786: Standard geometry

No. 13020: Set consisting of taper tap (form A) with very good price/performance ratio

and third tap (form C) No. 13023 803–13023 886: Standard geometry p. 755 p. 170 p. 62 p. 282 p. 283

with a very good price-performance ratio

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13020

13023030-280

13023703-786

13023803-886

Version Set Set Taper tap Third tap

Lead angle shape D/C D/C D C

13023... 13020... 13023... 13023...

Ident. No. Ident. No. Ident. No. Ident. No.

mm mm mm mm mm

MF3 0.35 2.65 40 3.5 2.7 030 ● - - - - - -

MF4 0.5 3.5 45 4.5 3.4 045 ● 045 ● - - - -

MF5 0.5 4.5 50 6 4.9 050 ● 050 ● - - - -

MF6 0.5 5.5 50 6 4.9 - - 060 ● - - - -

MF6 0.75 5.2 50 6 4.9 065 ● 065 ● - - - -

MF7 0.75 6.2 50 6 4.9 - - 070 ● - - - -

MF8 0.5 7.5 50 6 4.9 - - 080 ● - - - -

MF8 0.75 7.2 50 6 4.9 083 ● 083 ● - - - -

MF8 1 7 56 6 4.9 086 ● 086 ● 786 ● 886 ●

MF10 1 9 63 7 5.5 103 ● 103 ● 703 ● 803 ●

MF10 1.25 8.8 70 7 5.5 106 ● 106 ● - - - -

MF10 0.75 9.2 68 7 5.5 - - 100 ● - - - -

MF12 1 11 70 9 7 120 ● 120 ● 720 ● 820 ●

MF12 1.25 10.8 70 9 7 123 ● 123 ● - - - -

MF12 1.5 10.5 70 9 7 126 ● 126 ● 726 ● 826 ●

MF14 1 13 70 11 9 140 ● 140 ● - - - -

MF14 1.25 12.8 70 11 9 143 ● 143 ● - - - -

MF14 1.5 12.5 70 11 9 146 ● 146 ● 742 ● 842 ●

MF15 1 14 70 12 9 - - 150 ● - - - -

MF16 1 15 70 12 9 160 ● 160 ● - - - -

MF16 1.5 14.5 70 12 9 165 ● 165 ● 765 ● 865 ●

MF18 1 17 80 14 11 180 ● 180 ● 780 ● 880 ●

MF18 1.5 16.5 80 14 11 183 ● 183 ● 783 ● 883 ●

MF20 1 19 80 16 12 200 ● 200 ● - - - -

MF20 1.5 18.5 80 16 12 203 ● 203 ● 713 ● 813 ●

MF20 2 18 80 16 12 206 ● - - - - - -

MF22 1.5 20.5 80 18 14.5 223 ● 223 ● - - - -

MF22 1 21 80 18 14.5 220 ● - - - - - -

MF24 1 23 90 18 14.5 - - 240 ● - - - -

MF24 1.5 22.5 90 18 14.5 243 ● 243 ● - - - -

MF24 2 22 90 18 14.5 - - 246 ● - - - -

MF26 1.5 24.5 90 18 14.5 260 ● - - - - - -

MF27 2 25 90 20 16 - - 275 ● - - - -

MF28 1.5 26.5 90 20 16 280 ● - - - - - -

MF30 1.5 28.5 90 22 18 - - 303 ● - - - -

MF30 2 28 90 22 18 - - 306 ● - - - -

MF36 1.5 34.5 100 28 22 - - 360 ● - - - -

ORION = Prod. Gr. 1DA

a = Prod. Gr. 1KM

Source: Hahn+Kolb Werkzeuge GmbH

218 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.