Page 313 - Industrial Tools Catalog (1)

P. 313

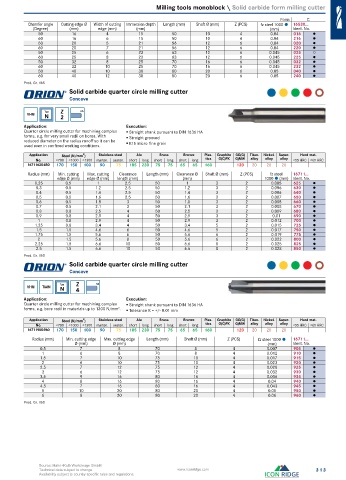

Milling tools monoblock \ Solid carbide form milling cutter

Form C

Chamfer angle Cutting edge Ø Width of cutting Immersion depth Length (mm) Shaft Ø (mm) Z (PCS) fz steel 1000 16530...

(Degree) (mm) edge (mm) (mm) (mm) Ident. No.

50 16 4 15 50 10 4 0.04 016 ●

60 16 6 15 50 10 4 0.04 216 ●

50 20 5 21 56 12 6 0.04 020 ●

60 20 7 21 56 12 6 0.04 220 ●

50 25 6 23 63 12 6 0.045 025 ○

60 25 8 23 63 12 6 0.045 225 ●

50 32 8 25 70 16 6 0.045 032 ●

60 32 10 25 70 16 6 0.045 232 ●

50 40 10 30 80 20 6 0.05 040 ●

60 40 12 30 80 20 6 0.05 240 ●

Prod. Gr. 165

Solid carbide quarter circle milling cutter

Concave

Typ Z HA

VHM N 2

Application: Execution:

Quarter circle milling cutter for machining complex Straight shank pursuant to DIN 1636 HA

forms, e.g. for very small radii on bores. With Straight grooved

reduced diameter on the radius runoff so it can be K15 micro-fine grain

used even in confined working conditions.

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16711625-850 170 150 100 90 75 185 230 75 75 65 65 160 120 20 20 20

Radius (mm) Min. cutting Max. cutting Clearance Length (mm) Clearance Ø Shaft Ø (mm) Z (PCS) fz steel 16711...

edge Ø (mm) edge Ø (mm) length (mm) (mm) 1000 (mm) Ident. No.

0.25 0.5 1 2.5 50 1 3 2 0.005 625 ●

0.3 0.5 1.2 2.5 50 1.2 3 2 0.006 630 ●

0.4 0.5 1.4 2.5 50 1.4 3 2 0.006 640 ●

0.5 0.5 1.6 2.5 50 1.6 3 2 0.007 650 ●

0.6 0.5 1.8 3 50 1.8 3 2 0.008 660 ●

0.7 0.5 2.1 3 50 2.1 3 2 0.008 670 ●

0.8 0.8 2.5 4 50 2.5 3 2 0.009 680 ●

0.9 0.8 2.9 4 50 2.9 3 2 0.01 690 ●

1 0.8 2.9 4 50 2.9 3 2 0.012 700 ●

1.25 0.8 3.4 4 50 3.4 5 2 0.015 725 ●

1.5 1.5 4.6 6 50 4.6 5 2 0.017 750 ●

1.75 1.5 5.6 6 50 5.6 6 2 0.019 775 ●

2 1.5 5.6 8 50 5.6 6 2 0.022 800 ●

2.25 1.5 6.6 10 50 6.6 8 2 0.025 825 ●

2.5 1.5 6.6 10 50 6.6 8 2 0.028 850 ●

Prod. Gr. 150

Solid carbide quarter circle milling cutter

Concave

Typ Z HA

VHM TiAlN N 4

Application: Execution:

Quarter circle milling cutter for machining complex Straight shank pursuant to DIN 1636 HA

forms, e.g. bore radii in materials up to 1300 N/mm . 2 Tolerance R = +/- 0.01 mm

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16711905-960 170 150 100 90 75 185 230 75 75 65 65 160 120 20 20 20

Radius (mm) Min. cutting edge Max. cutting edge Length (mm) Shaft Ø (mm) Z (PCS) fz steel 1000 16711...

Ø (mm) Ø (mm) (mm) Ident. No.

0.5 7 8 70 8 4 0.007 905 ●

1 6 8 70 8 4 0.012 910 ●

1.5 7 10 75 10 4 0.017 915 ●

2 6 10 75 10 4 0.023 920 ●

2.5 7 12 75 12 4 0.028 925 ●

3 6 12 75 12 4 0.032 930 ●

3.5 9 16 80 16 4 0.036 935 ●

4 8 16 80 16 4 0.04 940 ●

4.5 7 16 80 16 4 0.043 945 ●

5 10 20 80 20 4 0.05 950 ●

6 8 20 80 20 4 0.06 960 ●

Prod. Gr. 150

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 313

Availability subject to country specific rules and regulations.