Page 318 - Industrial Tools Catalog (1)

P. 318

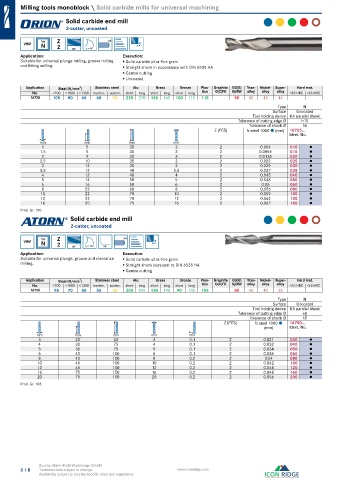

Milling tools monoblock \ Solid carbide mills for universal machining

Solid carbide end mill

2-cutter, uncoated

Typ Z HA

VHM N 2 γ = 5°

Application: Execution:

Suitable for universal plunge milling, groove milling Solid carbide ultra-fine grain

and fitting milling. Straight shank in accordance with DIN 6535 HA

Centre cutting

Uncoated

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16725 105 80 65 60 55 225 270 145 160 100 115 115 90 50 45 40

Type N

Surface Uncoated

Tool holding device HA parallel shank

Tolerance of cutting edge Ø h10

Tolerance of shank Ø h6

Z (PCS) fz steel 1000 (mm) 16725...

Ident. No.

mm mm mm mm

1 5 38 3 2 0.004 010 ●

1.5 5 38 3 2 0.0055 015 ●

2 9 38 3 2 0.0135 020 ●

2.5 10 38 3 2 0.022 025 ●

3 12 38 3 2 0.029 030 ●

3.5 12 40 3.5 2 0.037 035 ●

4 12 40 4 2 0.045 040 ●

5 14 50 5 2 0.048 050 ●

6 16 50 6 2 0.05 060 ●

8 22 60 8 2 0.056 080 ●

10 22 70 10 2 0.059 100 ●

12 22 70 12 2 0.062 120 ●

16 25 75 16 2 0.067 160 ●

Prod. Gr. 150

Solid carbide end mill

2-cutter, uncoated

Typ Z HA

VHM N 2 γ = 13° 45°

Application: Execution:

Suitable for universal plunge, groove and clearance Solid carbide ultra-fine grain

milling. Straight shank pursuant to DIN 6535 HA

Centre cutting

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16750 95 70 60 55 50 200 245 130 145 90 105 105 80 45 40 35

Type N

Surface Uncoated

Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h5

Z (PCS) fz steel 1000 16750...

(mm) Ident. No.

mm mm mm mm mm

3 20 60 3 0.1 2 0.021 030 ●

4 30 75 4 0.1 2 0.032 040 ●

5 30 75 5 0.1 2 0.034 050 ●

6 40 100 6 0.1 2 0.036 060 ●

8 40 100 8 0.2 2 0.04 080 ●

10 40 100 10 0.2 2 0.042 100 ●

12 45 100 12 0.2 2 0.044 120 ●

16 75 150 16 0.2 2 0.048 160 ●

20 75 150 20 0.2 2 0.056 200 ●

Prod. Gr. 108

Source: Hahn+Kolb Werkzeuge GmbH

318 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.