Page 329 - Industrial Tools Catalog (1)

P. 329

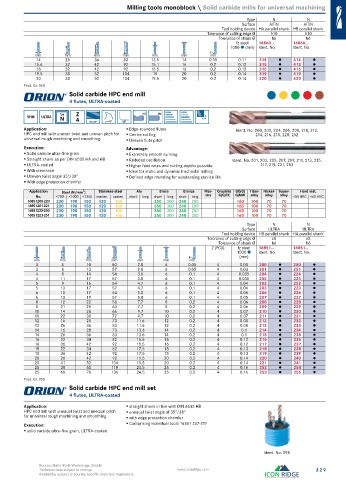

Milling tools monoblock \ Solid carbide mills for universal machining

Type N N

Surface AlTiN AlTiN

Tool holding device HA parallel shank HB parallel shank

Tolerance of cutting edge Ø h10 h10

Tolerance of shank Ø h6 h6

fz steel 16860... 16860...

1000 (mm) Ident. No. Ident. No.

mm mm mm mm mm mm mm

14 26 36 83 13.5 14 0.15 0.11 314 ● 414 ●

15.6 32 42 92 15.1 16 0.2 0.12 315 ● 415 ●

16 32 42 92 15.5 16 0.2 0.12 316 ● 416 ●

19.5 38 52 104 19 20 0.2 0.14 319 ● 419 ●

20 38 52 104 19.5 20 0.2 0.14 320 ● 420 ●

Prod. Gr. 150

Solid carbide HPC end mill

4 flutes, ULTRA-coated

Typ Z HB HA

VHM ULTRA

N 4 35°/38° γ = 8° 45°

Application: Edge-rounded flutes Ident. No. 200, 202, 204, 206, 208, 210, 212,

HPC

HPC end mill with uneven twist and uneven pitch for Centre cutting 214, 216, 218, 220, 252

universal rough machining and smoothing. Uneven flute pitch

Execution: Advantage:

Solid carbide ultra-fine grain Extremely smooth running

Straight shank as per DIN 6535 HA and HB Reduced oscillation Ident. No. 201, 203, 205, 207, 209, 211, 213, 215,

ULTRA-coated Higher feed rates and cutting depths possible 217, 219, 221, 253

With clearance Ideal for static and dynamic trochoidal milling

Uneven twist angle 35°/38° Defined edge rounding for outstanding service life

With edge protection chamfer

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16851200-220 230 190 150 120 100 350 300 240 280 160 100 70 70

16851201-221 230 190 150 120 100 350 300 240 280 160 100 70 70

16851222-250 230 190 150 120 100 350 300 240 280 160 100 70 70

16851223-251 230 190 150 120 100 350 300 240 280 160 100 70 70

Type N N

Surface ULTRA ULTRA

Tool holding device HB parallel shank HA parallel shank

Tolerance of cutting edge Ø e8 e8

Tolerance of shank Ø h6 h6

Z (PCS) fz steel 16851... 16851...

1000 Ident. No. Ident. No.

(mm)

mm mm mm mm mm mm mm

3 5 10 50 2.8 6 0.05 4 0.03 200 ● 250 ●

3 8 13 57 2.8 6 0.05 4 0.03 201 ● 251 ●

4 8 14 54 3.8 6 0.1 4 0.035 204 ● 224 ●

4 11 17 57 3.8 6 0.1 4 0.035 205 ● 225 ●

5 9 16 54 4.7 6 0.1 4 0.04 202 ● 222 ●

5 13 17 57 4.7 6 0.1 4 0.04 203 ● 223 ●

6 10 17 54 5.8 6 0.1 4 0.05 206 ● 226 ●

6 13 19 57 5.8 6 0.1 4 0.05 207 ● 227 ●

8 12 22 58 7.7 8 0.2 4 0.06 208 ● 228 ●

8 21 25 63 7.7 8 0.2 4 0.06 209 ● 229 ●

10 14 26 66 9.7 10 0.2 4 0.07 210 ● 230 ●

10 22 30 72 9.7 10 0.2 4 0.07 211 ● 231 ●

12 16 28 73 11.6 12 0.2 4 0.08 212 ● 232 ●

12 26 36 83 11.6 12 0.2 4 0.08 213 ● 233 ●

14 16 28 73 13.6 14 0.2 4 0.1 214 ● 234 ●

14 26 36 83 13.6 14 0.2 4 0.1 215 ● 235 ●

16 22 34 82 15.5 16 0.2 4 0.12 216 ● 236 ●

16 36 42 92 15.5 16 0.2 4 0.12 217 ● 237 ●

18 22 34 82 17.5 18 0.2 4 0.13 218 ● 238 ●

18 36 42 92 17.5 18 0.2 4 0.13 219 ● 239 ●

20 26 42 92 19.5 20 0.2 4 0.14 220 ● 240 ●

20 41 52 104 19.5 20 0.2 4 0.14 221 ● 241 ●

25 30 50 110 24.5 25 0.2 4 0.16 252 ● 254 ●

25 68 78 136 24.5 25 0.2 4 0.16 253 ● 255 ●

Prod. Gr. 150

Solid carbide HPC end mill set

4 flutes, ULTRA-coated

Application: straight shank in line with DIN 6535 HB

HPC end mill with unequal twist and unequal pitch unequal twist angle of 35°/38°

for universal rough machining and smoothing with edge protection chamfer

Execution: Comprising individual tools 16851 207-217

solid carbide ultra-fine grain, ULTRA-coated

Ident. No. 298

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 329

Availability subject to country specific rules and regulations.