Page 378 - Industrial Tools Catalog (1)

P. 378

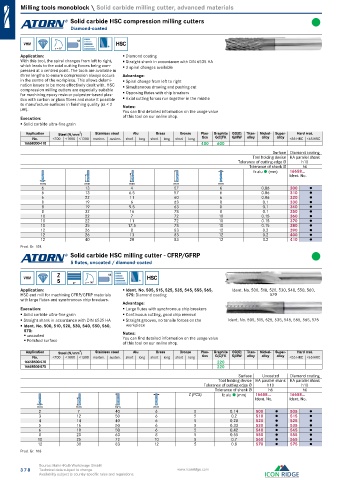

Milling tools monoblock \ Solid carbide milling cutter, advanced materials

Solid carbide HSC compression milling cutters

Diamond-coated

HA

VHM HSC

γ = 5°

Application: Diamond coating

With this tool, the spiral changes from left to right, Straight shank in accordance with DIN 6535 HA

which leads to the axial cutting forces being com- 3 spiral changes available

pressed at a centred point. The tools are available in

three lengths to ensure compression always occurs Advantage:

in the centre of the workpiece. This allows delami- Spiral change from left to right

nation issues to be more effectively dealt with. HSC Simultaneous drawing and pushing cut

compression milling cutters are especially suitable

for machining epoxy resin or polyester-based plas- Opposing flutes with chip breakers

tics with carbon or glass fibres and make it possible Axial cutting forces run together in the middle

to manufacture surfaces in finishing quality (ra < 2 Notes:

µm). You can find detailed information on the usage value

Execution: of this tool on our online shop.

Solid carbide ultra-fine grain

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16658300-410 400 600

Surface Diamond coating

Tool holding device HA parallel shank

Tolerance of cutting edge Ø h10

Tolerance of shank Ø h6

fz alu (mm) 16658...

Ident. No.

mm mm mm mm mm

6 13 4 57 6 0.06 300 ●

6 13 6.5 57 6 0.06 310 ●

6 22 11 60 6 0.06 320 ●

8 19 6 63 8 0.1 330 ●

8 19 9.5 63 8 0.1 340 ●

8 32 16 78 8 0.1 350 ●

10 22 7 72 10 0.15 360 ●

10 22 11 72 10 0.15 370 ●

10 35 17.5 78 10 0.15 380 ●

12 26 8 83 12 0.2 390 ●

12 26 13 83 12 0.2 400 ●

12 40 20 83 12 0.2 410 ●

Prod. Gr. 108

Solid carbide HSC milling cutter - CFRP/GFRP

5 flutes, uncoated / diamond-coated

Z HA

VHM HSC

5 0° γ = 14°

Application: Ident. No. 505, 515, 525, 535, 545, 555, 565, Ident. No. 500, 510, 520, 530, 540, 550, 560,

HSC end mill for machining CFRP/GFRP materials 575: Diamond coating 570

with large flutes and synchronous chip breakers.

Advantage:

Execution: Large flutes with synchronous chip breakers

Solid carbide ultra-fine grain Continuous cutting, good chip removal

Straight shank in accordance with DIN 6535 HA Straight grooves, no tensile forces on the Ident. No. 505, 515, 525, 535, 545, 555, 565, 575

Ident. No. 500, 510, 520, 530, 540, 550, 560, workpiece

570: Notes:

uncoated You can find detailed information on the usage value

Polished surface

of this tool on our online shop.

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16658500-570 220

16658505-575 220

Surface Uncoated Diamond coating

Tool holding device HA parallel shank HA parallel shank

Tolerance of cutting edge Ø h10 h10

Tolerance of shank Ø h6 h6

Z (PCS) fz alu (mm) 16658... 16658...

Ident. No. Ident. No.

mm mm mm mm

2 7 40 6 5 0.14 500 ● 505 ●

3 12 50 6 5 0.2 510 ● 515 ●

4 14 40 6 5 0.28 520 ● 525 ●

5 16 50 6 5 0.33 530 ● 535 ●

6 18 50 6 5 0.42 540 ● 545 ●

8 20 63 8 5 0.55 550 ● 555 ●

10 25 72 10 5 0.7 560 ● 565 ●

12 30 83 12 5 0.8 570 ● 575 ●

Prod. Gr. 108

Source: Hahn+Kolb Werkzeuge GmbH

378 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.