Page 472 - Industrial Tools Catalog (1)

P. 472

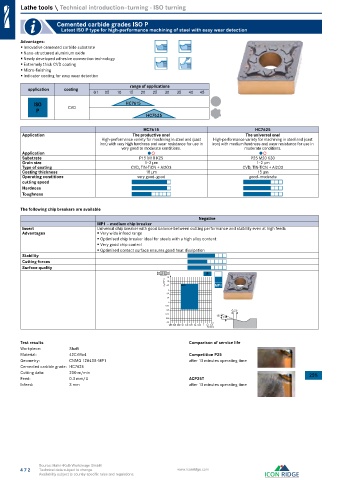

Lathe tools \ Technical introduction–turning - ISO turning

Cemented carbide grades ISO P

Latest ISO P type for high-performance machining of steel with easy wear detection

Advantages:

Innovative cemented carbide substrate

Nano-structured aluminium oxide

Newly developed adhesive connection technology

Extremely thick CVD coating

Micro-finishing

Indicator coating for easy wear detection

range of applications

application coating

01 05 10 15 20 25 30 35 40 45

ISO CVD HC7615

P

HC7625

HC7615 HC7625

Application The productive one! The universal one!

High-performance variety for machining in steel and (cast High-performance variety for machining in steel and (cast

iron) with very high hardness and wear resistance for use in iron) with medium hardness and wear resistance for use in

very good to moderate conditions. moderate conditions.

Application

Substrate P15 M10 K25 P25 M20 K30

Grain size 1–2 µm 1–2 µm

Type of coating CVD, TIN-TiCN + Al2O3 CVD, TIN-TiCN + Al2O3

Coating thickness 18 µm 15 µm

Operating conditions very good–good good–moderate

cutting speed

Hardness

Toughness

The following chip breakers are available

Negative

MP1 – medium chip breaker

Insert Universal chip breaker with good balance between cutting performance and stability even at high feeds

Advantages Very wide infeed range

Optimised chip breaker ideal for steels with a high alloy content

Very good chip control

Optimised contact surface ensures good heat dissipation

Stability

Cutting forces

Surface quality

P

16

a ( mm ) p 6,3 10 MP1 MP1

4

2,5

1,6

1

0,63

0,4 0,25

0,25

15°

0,16 7°

0,1

0,025 0,04 0,063 0,1 0,16 0,25 0,4 0,63 1 1,6 2,5

f ( mm )

Test results Comparison of service life

Workpiece: Shaft

Material: 42CrMo4 Competition P25

Geometry: CNMG 120408-MP1 after 13 minutes operating time

Cemented carbide grade: HC7625

Cutting data: 200 m/min 25%

Feed: 0.3 mm/U ACP25T

Infeed: 3 mm after 13 minutes operating time

Source: Hahn+Kolb Werkzeuge GmbH

472 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.