Page 49 - Industrial Tools Catalog (1)

P. 49

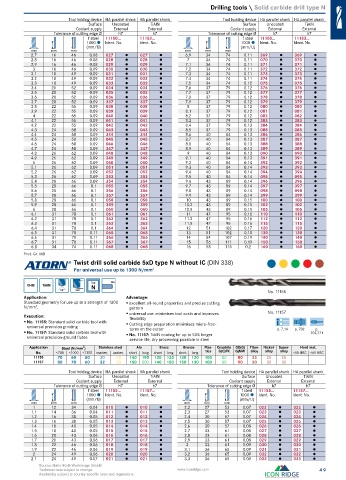

Drilling tools \ Solid carbide drill type N

Tool holding device HA parallel shank HA parallel shank Tool holding device HA parallel shank HA parallel shank

Surface Uncoated TiAlN Surface Uncoated TiAlN

Coolant supply External External Coolant supply External External

Tolerance of cutting edge Ø h7 h7 Tolerance of cutting edge Ø h7 h7

f steel 11150... 11153... f steel 11150... 11153...

1000 Ident. No. Ident. No. 1000 Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

2.7 16 46 0.08 027 ● 027 ● 6.9 34 74 0.11 369 ● 369 ●

2.8 16 46 0.08 028 ● 028 ● 7 34 74 0.11 070 ● 070 ●

2.9 16 46 0.08 029 ● 029 ● 7.1 34 74 0.11 371 ● 371 ●

3 16 46 0.09 030 ● 030 ● 7.2 34 74 0.11 372 ● 372 ●

3.1 18 49 0.09 031 ● 031 ● 7.3 34 74 0.11 373 ● 373 ●

3.2 18 49 0.09 032 ● 032 ● 7.4 34 74 0.11 374 ● 374 ●

3.3 18 49 0.09 033 ● 033 ● 7.5 34 74 0.12 075 ● 075 ●

3.4 20 52 0.09 034 ● 034 ● 7.6 37 79 0.12 376 ● 376 ●

3.5 20 52 0.09 035 ● 035 ● 7.7 37 79 0.12 377 ● 377 ●

3.6 20 52 0.09 036 ● 036 ● 7.8 37 79 0.12 378 ● 378 ●

3.7 20 52 0.09 337 ● 337 ● 7.9 37 79 0.12 379 ● 379 ●

3.8 22 55 0.09 038 ● 038 ● 8 37 79 0.12 080 ● 080 ●

3.9 22 55 0.09 039 ● 039 ● 8.1 37 79 0.12 081 ● 081 ●

4 22 55 0.09 040 ● 040 ● 8.2 37 79 0.12 082 ● 082 ●

4.1 22 55 0.09 041 ● 041 ● 8.3 37 79 0.12 383 ● 383 ●

4.2 22 55 0.09 042 ● 042 ● 8.4 37 79 0.13 384 ● 384 ●

4.3 24 58 0.09 043 ● 043 ● 8.5 37 79 0.13 085 ● 085 ●

4.4 24 58 0.09 344 ● 344 ● 8.6 40 84 0.13 386 ● 386 ●

4.5 24 58 0.09 045 ● 045 ● 8.7 40 84 0.13 387 ● 387 ●

4.6 24 58 0.09 046 ● 046 ● 8.8 40 84 0.13 388 ● 388 ●

4.7 24 58 0.09 347 ● 347 ● 8.9 40 84 0.13 389 ● 389 ●

4.8 26 62 0.09 048 ● 048 ● 9 40 84 0.13 090 ● 090 ●

4.9 26 62 0.09 349 ● 349 ● 9.1 40 84 0.13 391 ● 391 ●

5 26 62 0.09 050 ● 050 ● 9.2 40 84 0.14 392 ● 392 ●

5.1 26 62 0.09 051 ● 051 ● 9.3 40 84 0.14 393 ● 393 ●

5.2 26 62 0.09 052 ● 052 ● 9.4 40 84 0.14 394 ● 394 ●

5.3 26 62 0.09 353 ● 353 ● 9.5 40 84 0.14 095 ● 095 ●

5.4 28 66 0.09 354 ● 354 ● 9.6 43 89 0.14 396 ● 396 ●

5.5 28 66 0.1 055 ● 055 ● 9.7 43 89 0.14 397 ● 397 ●

5.6 28 66 0.1 356 ● 356 ● 9.8 43 89 0.14 098 ● 098 ●

5.7 28 66 0.1 357 ● 357 ● 9.9 43 89 0.14 399 ● 399 ●

5.8 28 66 0.1 058 ● 058 ● 10 43 89 0.15 100 ● 100 ●

5.9 28 66 0.1 359 ● 359 ● 10.2 43 89 0.15 102 ● 102 ●

6 28 66 0.1 060 ● 060 ● 10.5 43 89 0.15 105 ● 105 ●

6.1 31 70 0.1 061 ● 061 ● 11 47 95 0.16 110 ● 110 ●

6.2 31 70 0.1 362 ● 362 ● 11.2 47 95 0.16 112 ● 112 ●

6.3 31 70 0.1 363 ● 363 ● 11.5 47 95 0.16 115 ● 115 ●

6.4 31 70 0.1 364 ● 364 ● 12 51 102 0.17 120 ● 120 ●

6.5 31 70 0.11 065 ● 065 ● 13 51 102 0.18 130 ● 130 ●

6.6 31 70 0.11 366 ● 366 ● 14 54 107 0.19 140 ● 140 ●

6.7 31 70 0.11 367 ● 367 ● 15 56 111 0.19 150 ● 150 ●

6.8 34 74 0.11 068 ● 068 ● 16 58 115 0.2 160 ● 160 ●

Prod. Gr. 1AB

Twist drill solid carbide 5xD type N without IC (DIN 338)

For universal use up to 1300 N/mm 2

Typ HA

VHM TiAlN N

118° 5xD No. 11155

Application: Advantage:

Standard geometry for use up to a strength of 1300 excellent all-round properties and precise cutting

N/mm . 2 pattern

Execution: universal use: minimises tool costs and improves No. 11157

flexibility

No. 11155: Standard solid carbide tool with Cutting edge preparation minimises micro-frac-

universal precision grinding tures on the cutter p. 7,14 p. 702 p.

No. 11157: Standard solid carbide tool with No. 11157: TiAlN coating for up to 50% longer 702,771

universal precision-ground flutes service life, dry processing possible in steel

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11155 70 60 50 30 28 140 190 130 120 130 120 100 80 80 25 25 25

11157 80 70 60 32 30 150 200 140 150 150 130 100 80 90 30 30 30

Tool holding device HA parallel shank HA parallel shank Tool holding device HA parallel shank HA parallel shank

Surface Uncoated TiAlN Surface Uncoated TiAlN

Coolant supply External External Coolant supply External External

Tolerance of cutting edge Ø h7 h7 Tolerance of cutting edge Ø h7 h7

f steel 11155... 11157... f steel 11155... 11157...

1000 Ident. No. Ident. No. 1000 Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

1 12 34 0.04 010 ● 010 ● 2.2 27 53 0.07 022 ● 022 ●

1.1 14 36 0.04 011 ● 011 ● 2.3 27 53 0.07 023 ● 023 ●

1.2 16 38 0.05 012 ● 012 ● 2.4 30 57 0.07 024 ● 024 ●

1.3 16 38 0.05 013 ● 013 ● 2.5 30 57 0.07 025 ● 025 ●

1.4 18 40 0.05 014 ● 014 ● 2.6 30 57 0.08 026 ● 026 ●

1.5 18 40 0.05 015 ● 015 ● 2.7 33 61 0.08 027 ● 027 ●

1.6 20 43 0.06 016 ● 016 ● 2.8 33 61 0.08 028 ● 028 ●

1.7 20 43 0.06 017 ● 017 ● 2.9 33 61 0.08 029 ● 029 ●

1.8 22 46 0.06 018 ● 018 ● 3 33 61 0.09 030 ● 030 ●

1.9 22 46 0.06 019 ● 019 ● 3.1 36 65 0.09 031 ● 031 ●

2 24 49 0.06 020 ● 020 ● 3.2 36 65 0.09 032 ● 032 ●

2.1 24 49 0.07 021 ● 021 ● 3.3 36 65 0.09 033 ● 033 ●

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 49

Availability subject to country specific rules and regulations.